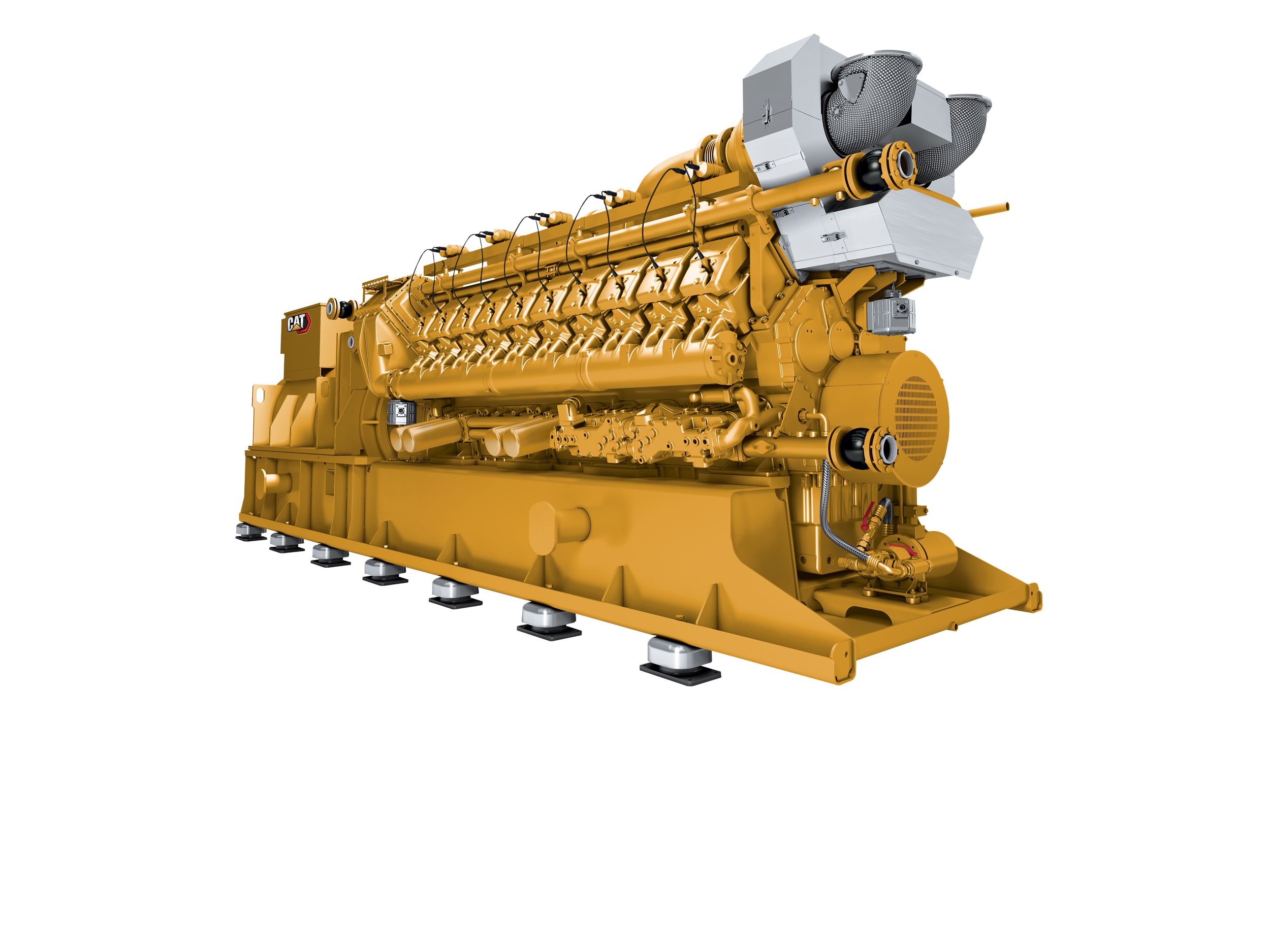

CG170-20 | 1400kW-2000kW Gas Generator

Contact Us For Price

SPECS SUMMARY

| Continuous Rating | 2000 ekW @1.0pf |

| Fuel Type | Natural Gas, Biogas, Coal Gas |

| Maximum Electrical Efficiency | 43.70% |

| Maximum Standby Rating | 2000 |

Specifications

| Continuous Rating | 2000 ekW @1.0pf |

| Fuel Type | Natural Gas, Biogas, Coal Gas |

| Maximum Electrical Efficiency | 43.70% |

| Maximum Standby Rating | 2000 |

| Frequency | 50 / 60 Hz |

| RPM | 1500 |

| Engine Model | CG170-20 |

| Displacement | 3240 in³ (53.1 l) |

| Aspiration | TA |

| Bore | 6.7 in (170 mm) |

| Stroke | 7.7 in (195 mm) |

| Length | 294 in (7467.6 mm) |

| Width | 67 in (1710 mm) |

| Height | 86 in (2190 mm) |

| Dry Weight - Genset | 43651.1 lb (19800 kg) |

Benefits and Features

- Miller cycle timing with combustion chamber and spark plug improvement help on saving up to 15% fuel gas per year

- CG170 (non-miller) is optimized for Island-Mode capability

- Gearbox helps limit wear and tear on engine components, lowering operating costs and increasing availability

- Extended maintenance intervals thanks to sooth-free combustion and enlarged oil tank

- Low fuel consumption due to improved combustion chamber and pre-chamber spark-plugs

- Flexible fields of application also with fluctuating gas qualities due to Total Electronic Management (TEM)

- Optimized oil management

- Consumes up to 1900 liter less lube oil per year than comparable models<li>

- Longer lubricant change and oil change intervals<li>

Standard Equipment

- Turbocharger with a water-cooled bearing case for all cylinder

- One-element single-stage air cleaner with enclosure and sevice indicator

- TEM (Total Electronic Management)

- Jacket water and SCAC thermostats

- flange connections for JW inlet and outlet

- Electrical jacket water and aftercooler coolant pump

- Closed crankcase ventilation system

- PEARL/Low resistence exhaust system

- Exhaust waste gate for the CG170-20

- Pre-chamber spark plugs

- Electronic fuel metering valve

- Independently controlled cylinder monitoring and ignition system

- Winding temperature detectors

- 3-phase sensing and KVAR/PF control

- Reactive droop

- closed-coupled generator result in no torque transmission to the base frame

- grid code generator

- Anti-condensation space heater

- Busbar connections

- 24V starting motors

- Battery disconnect switch

- Crankshaft vibration damper and guard

Optional Equipment

- CHP skid

- 50Hz: Germany, Belgium, Great Britain, Italy, Poland, and Netherlands