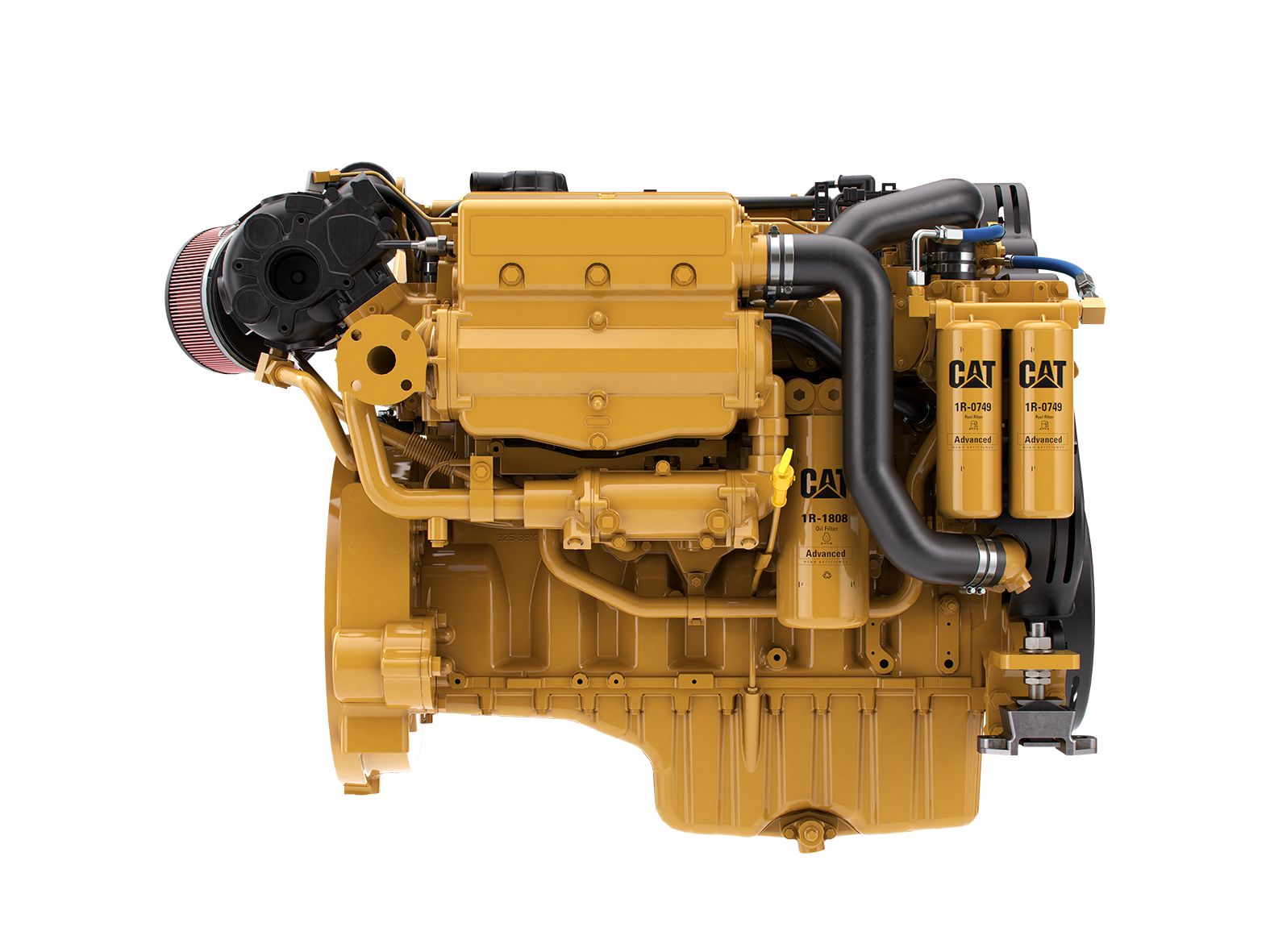

C9.3 ACERT

Contact Us For Price

SPECS SUMMARY

| Power Range | 375-476 bhp (280-355 bkW) |

| Speed Range | 1800, 2100, 2300 rpm |

| Rated Engine Speed | 1800, 2100, 2300 rpm |

| Emissions | IMO II, U.S. EPA Tier 3, China Stage II |

Specifications

| Power Range | 375-476 bhp (280-355 bkW) |

| Speed Range | 1800, 2100, 2300 rpm |

| Rated Engine Speed | 1800, 2100, 2300 rpm |

| Emissions | IMO II, U.S. EPA Tier 3, China Stage II |

| Configuration | In-line 6, 4-Stroke-Cycle Diesel |

| Displacement | 567.5 in³ (9.3 l) |

| Aspiration | Turbocharged-aftercooled |

| Governor | Electronic |

| Bore | 4.5 in (115 mm) |

| Stroke | 5.8 in (149 mm) |

| Refill Capacity | Lube Oil System w/oil filter change: 24.5 L (6.5 gal) |

| Oil Change Interval | 500 hrs |

| Flywheel Housing | SAE No. 1 (113 teeth) |

| Rotation from Flywheel End | Counterclockwise |

| Cooling | Heat exchanger and separate or combined keel cooled options |

| Length - Engine | 57.2 in (1452 mm) |

| Engine Dry Weight - Approximate | 945-1122 kg (2083-2474 lbs) |

| Height | 43 in (1093 mm) |

| Width - Engine | 38.5 in (978 mm) |

Benefits and Features

- Electronic control system provides industry-leading torque and throttle response at low speeds, while maintaining fuel efficiency at high speeds

- Common rail fuel system enables optimum combustion and low emissions

- RH and LH locations service options for fuel and oil filters, as well as dipstick location for easily accessible service

- Compatible with Cat® displays

- Available remote-mounted display panel with start, stop, and engine diagnostics

- 12V or 24V electrical system

- Certified by all marine classification societies

Standard Equipment

- Water-cooled turbocharger and exhaust manifold

- Electronic control system

- Thermostats and housing

- Gear-driven Sea water pump (self-priming)

- Common rail fuel system

- Shell and tube jacket water heat exchanger

- Corrosion-resistant Sea water aftercooler

- Engine oil cooler

- Vibration damper and guard

- Primary fuel filters

Optional Equipment

- Alternators - 24V 70 or 105 amp, 12V 110 amp

- Closed crankcase ventilation

- Transmission gear oil cooler (engine mounted for HEX)

- Additional engine and transmission sensor packages

- Instrument panels

- Electric starting motors - 12V or 24V

- Air starting motor

- Dual electric starting motors or combined electric/air

- Electric fuel priming pump

- Fuel cooler

- PTO Drives - V-belt pulley stack, stub shaft

- Duplex fuel and oil filters

- Double wall fuel rail