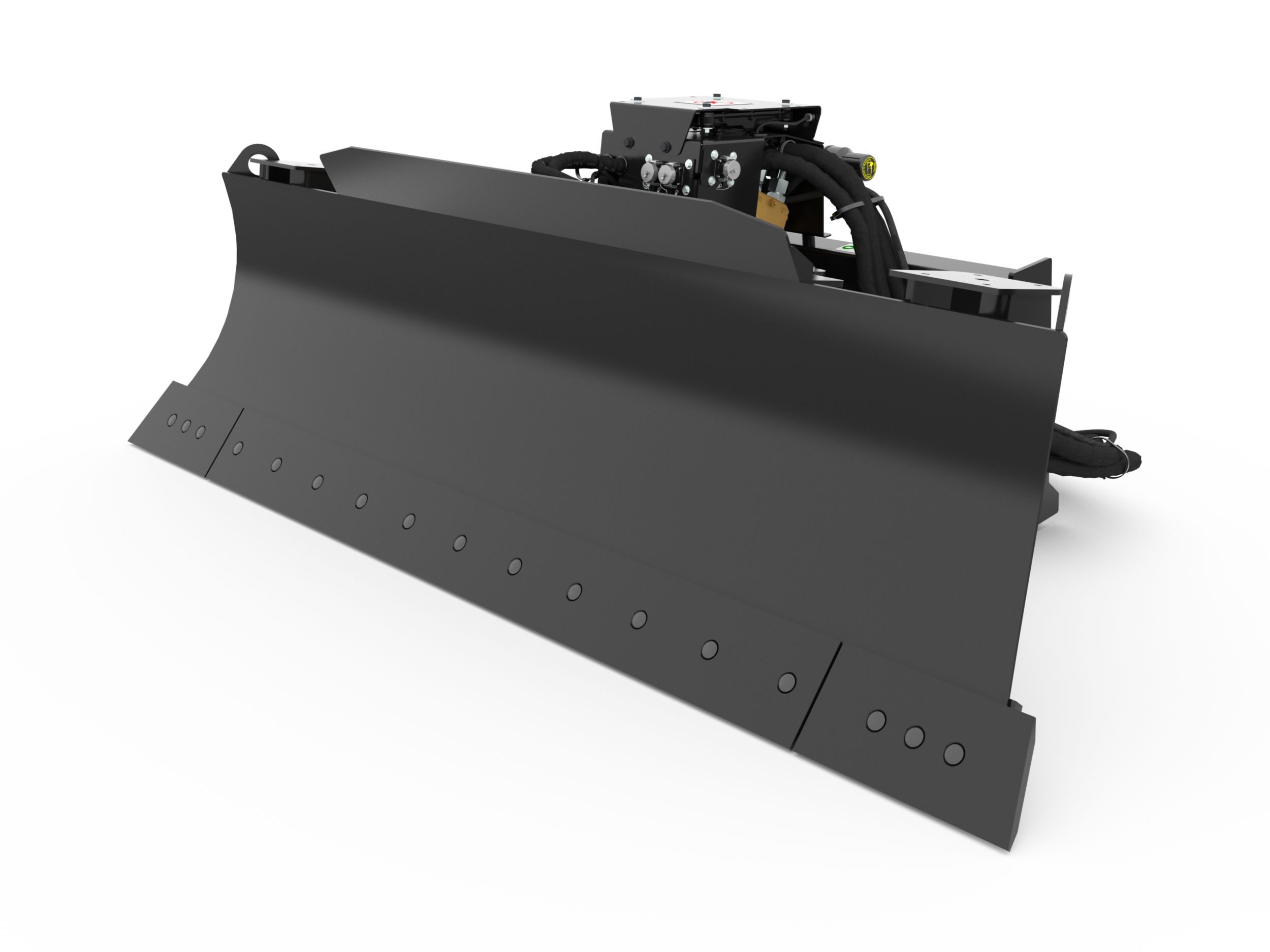

2337 mm (92 in), Smart

Cat® Smart Dozer Blade at Work

Cat® Smart Dozer Blade at Work Cat® Smart Dozer Blade Operator Tips

Cat® Smart Dozer Blade Operator Tips Cat® Smart Dozer Blade with Assist

Cat® Smart Dozer Blade with Assist An Attachment for Every Job - Cat® Work Tool Attachments

An Attachment for Every Job - Cat® Work Tool AttachmentsContact Us For Price

SPECS SUMMARY

| Blade Width | 92 in (2337 mm) |

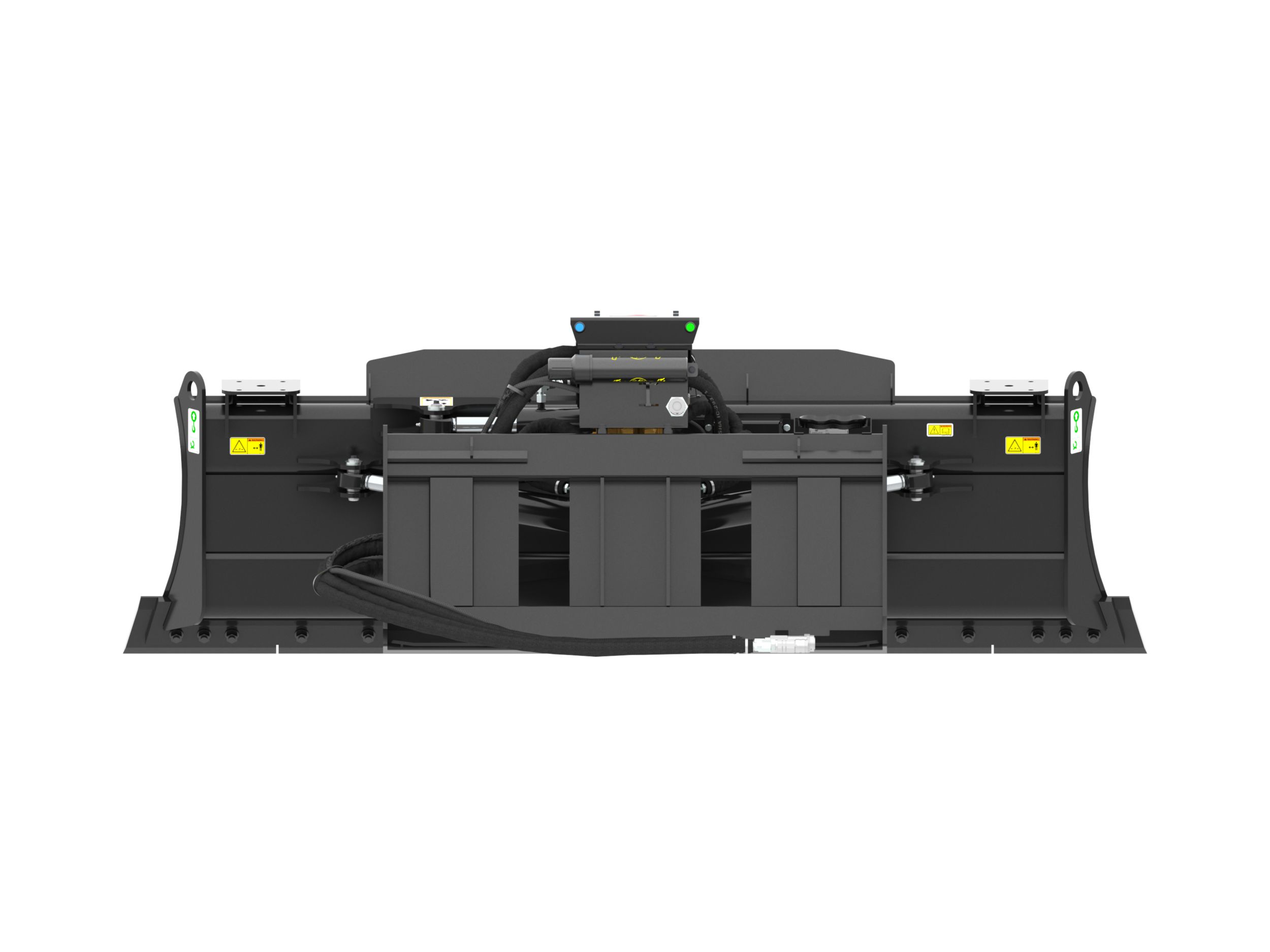

| Width - Fully Angled | 80.7 in (2049 mm) |

| Maximum Blade Angle - Right/Left of Center | 30 degrees |

| Tilt Angle Range +/- | 10 degrees |

Specifications

| Blade Width | 92 in (2337 mm) |

| Width - Fully Angled | 80.7 in (2049 mm) |

| Maximum Blade Angle - Right/Left of Center | 30 degrees |

| Tilt Angle Range +/- | 10 degrees |

| Blade Height | 24.4 in (619 mm) |

| Overall Height | 30.9 in (785 mm) |

| Length | 40.5 in (1028 mm) |

| Weight | 1164 lb (528 kg) |

| Cutting Edge Thickness | 0.6 in (16 mm) |

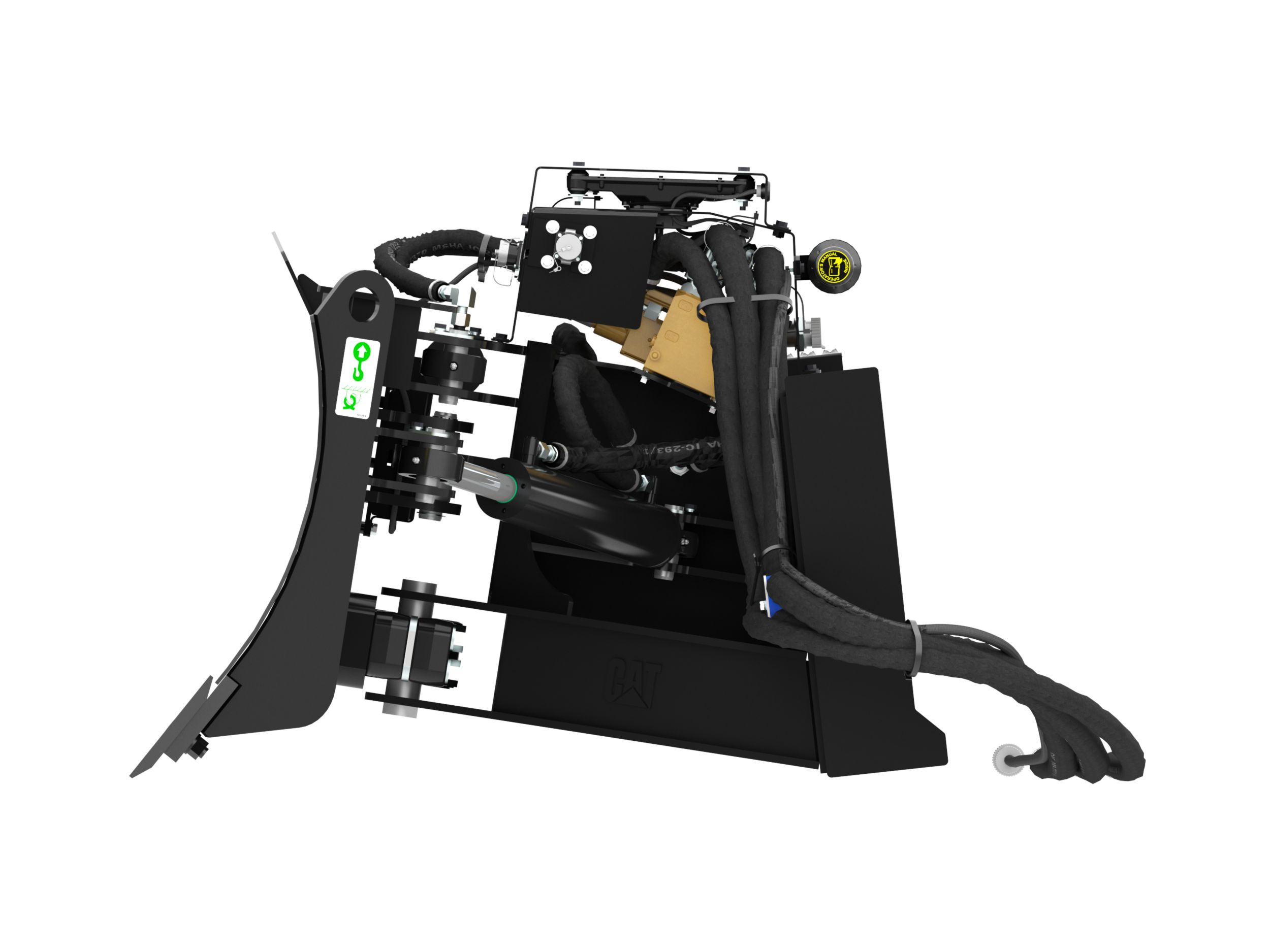

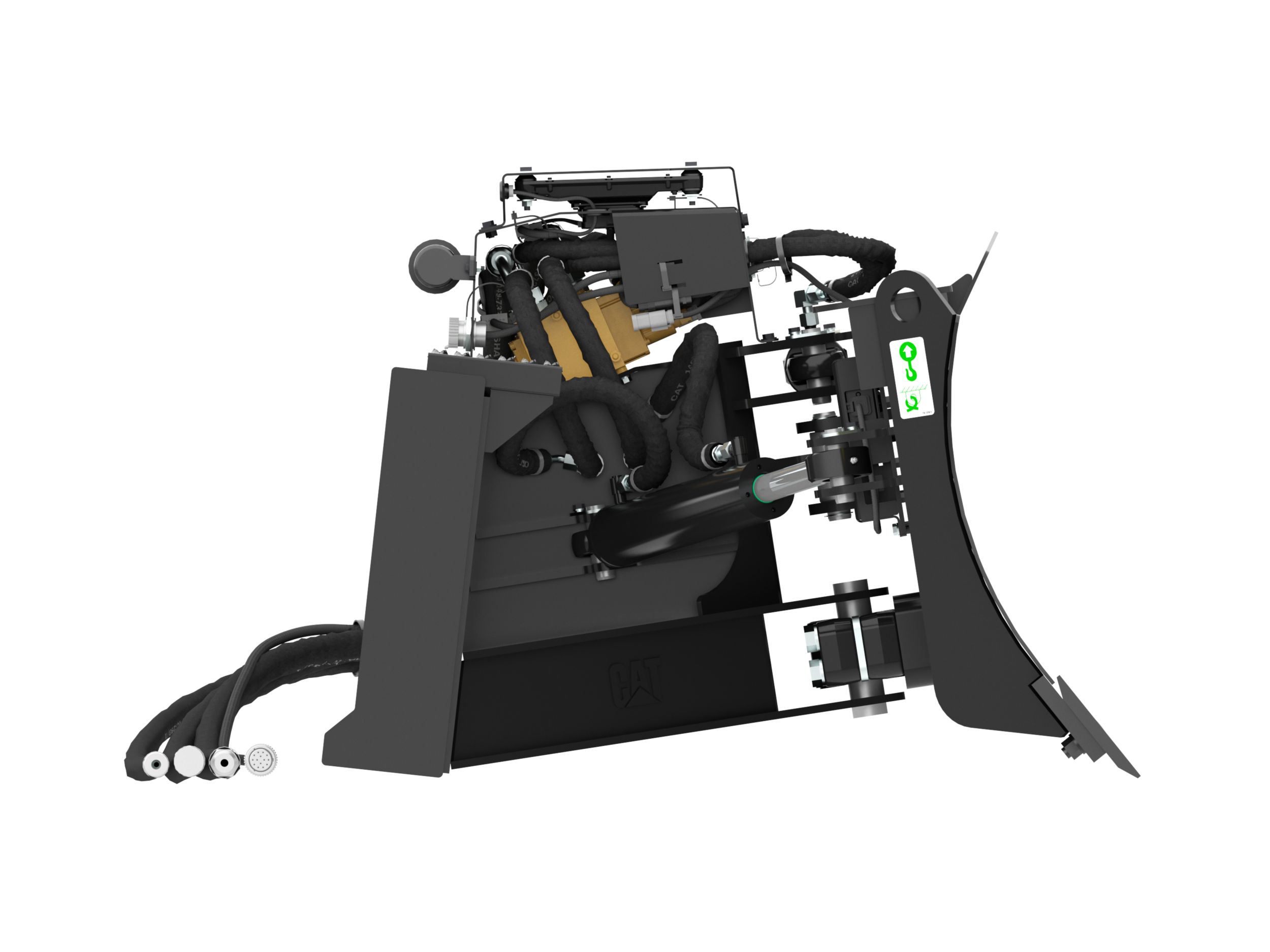

| Required Hydraulics | High Flow XPS |

| Optimal Hydraulic Flow | 42-86 L/min (11-23 gpm) |

| Optimal Hydraulic Pressure | 145-235 bar (2100-3400 psi) |

| Interface Type | Skid Steer Coupler |

Benefits and Features

Designed for rough and finish grading in dirt and gravel as well as for light dozing.

Attachment recognition makes the Smart Dozer Blade, Smart. Cat® Compact Track Loaders equipped with Smart technology recognizes the Smart Dozer attached to the machine, thus unlocking additional dedicated machine display screens allowing the operator to interface with the machine and how the attachment is controlled. As a Smart attachment, the existing joysticks on the machine equipped with Smart technology allow for mode select and pattern change to perform functions on the attachment.

Track-type tractor variable power angle tilt (VPAT) design with simultaneous tilt and angling capability delivers superior control and maneuverability.

Three-piece, replaceable, bolt-on, hardened cutting edge delivers long life and high performance.

An integrated spill guard prevents material from spilling over the top of the blade in full blade scenarios.

Modeled after track-type tractor blades, this allows flush cutting against a vertical surface when the blade is fully tilted.

To accept external reference masts for use by GPS, Laser, or other leveling systems.

Allows for adjustment of trunnion due to interface wear during normal usage.

Stores the OMM (Operation and Maintenance Manual) in a protective case on the attachment, where it can be conveniently accessed.