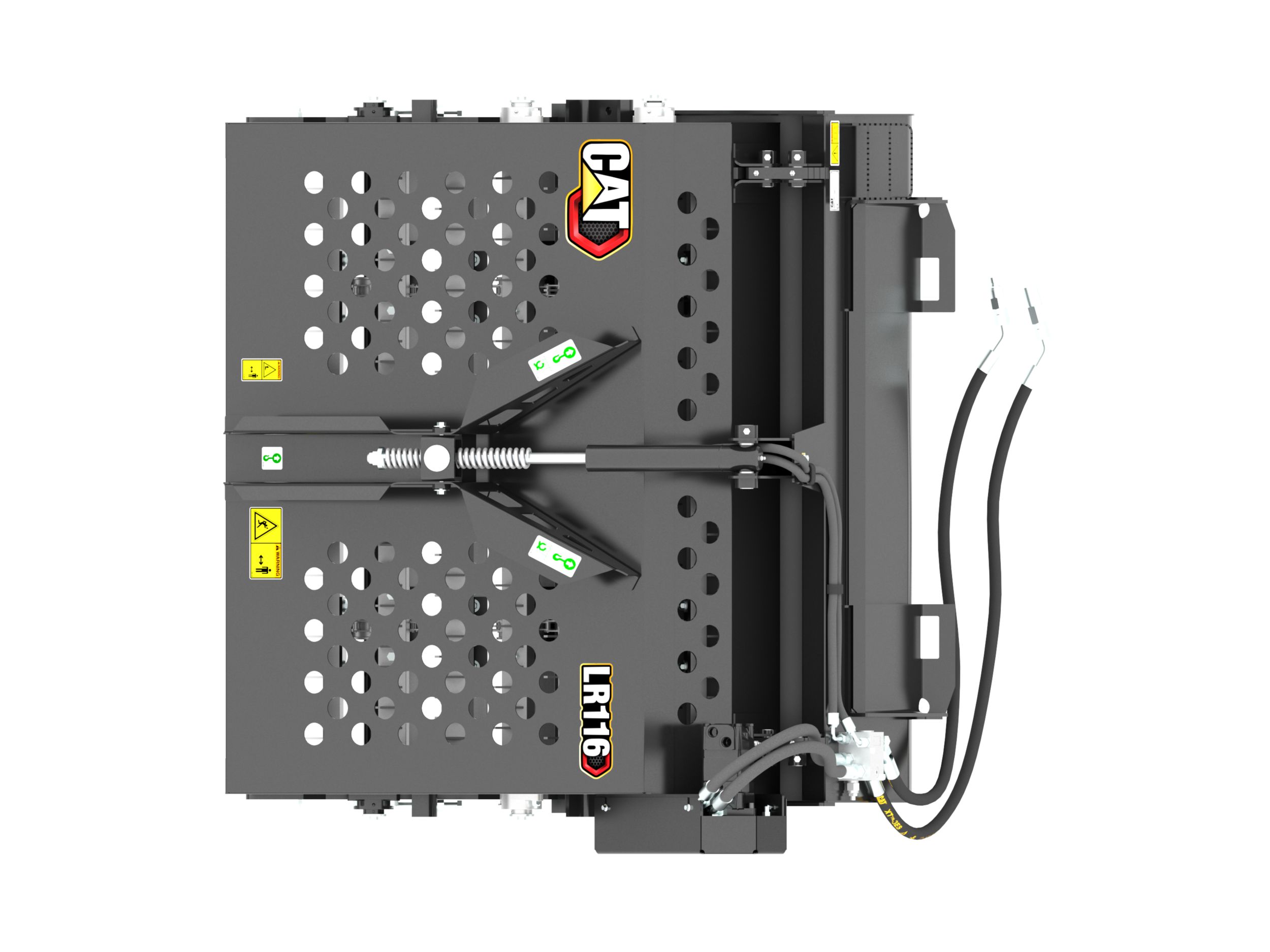

LR116

Cat® Landscape Rake at Work

Cat® Landscape Rake at Work Cat® Landscape Rake Overview

Cat® Landscape Rake Overview Cat® Landscape Rake Operator Tips

Cat® Landscape Rake Operator Tips Cat® Landscape Rake Operation Guide

Cat® Landscape Rake Operation Guide An Attachment for Every Job - Cat® Work Tool Attachments

An Attachment for Every Job - Cat® Work Tool AttachmentsContact Us For Price

SPECS SUMMARY

| Working Width | 62 in (1576 mm) |

| Bucket Capacity - Struck | 0.4 yd³ (0.31 m³) |

| Weight | 1311.7 lb (595 kg) |

| Raking Width | 54.5 in (1384 mm) |

Specifications

| Working Width | 62 in (1576 mm) |

| Bucket Capacity - Struck | 0.4 yd³ (0.31 m³) |

| Weight | 1311.7 lb (595 kg) |

| Raking Width | 54.5 in (1384 mm) |

| Overall Width | 66.3 in (1683 mm) |

| Height | 38.9 in (989 mm) |

| Length | 63.8 in (1620 mm) |

| Optimal Hydraulic Flow | 42-86 L/min (11-23 gpm) |

| Optimal Hydraulic Pressure | 145-235 bar (2100-3400 psi) |

| Motor Displacement | 19.2 in³/rev (315 cm³/rev) |

| Driven Shaft Speed | 165 rpm @ 80 L/min (21 gpm) |

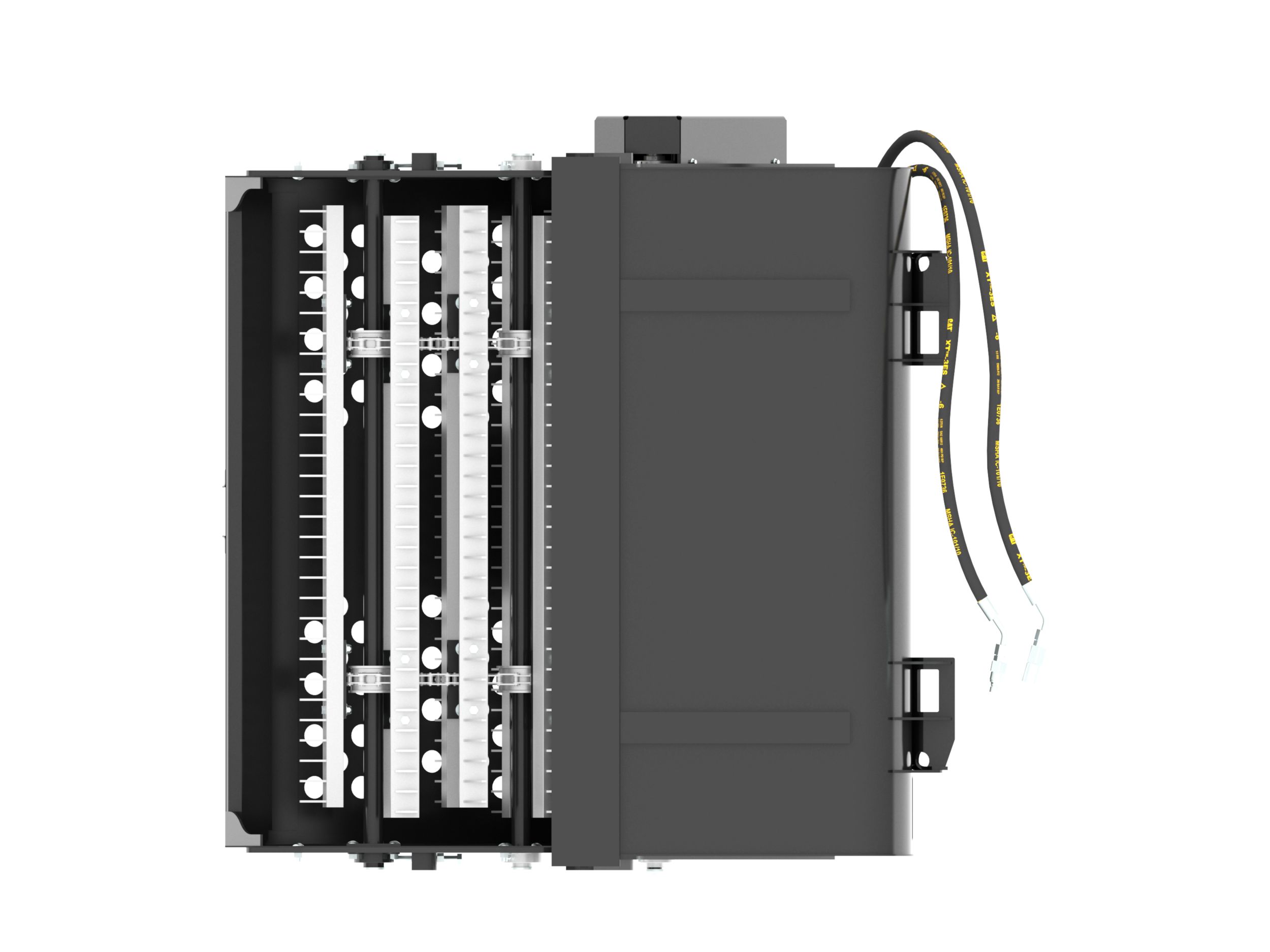

| Number of Hard Face Tines | 372 |

| Rock Size Range | 19-152 mm (0.75-6 in) |

| Drive Method | Chain Reduction |

| Drive Chain | #80H |

| Conveyor Chain | #2060H |

| Required Hydraulics | Standard Flow |

Benefits and Features

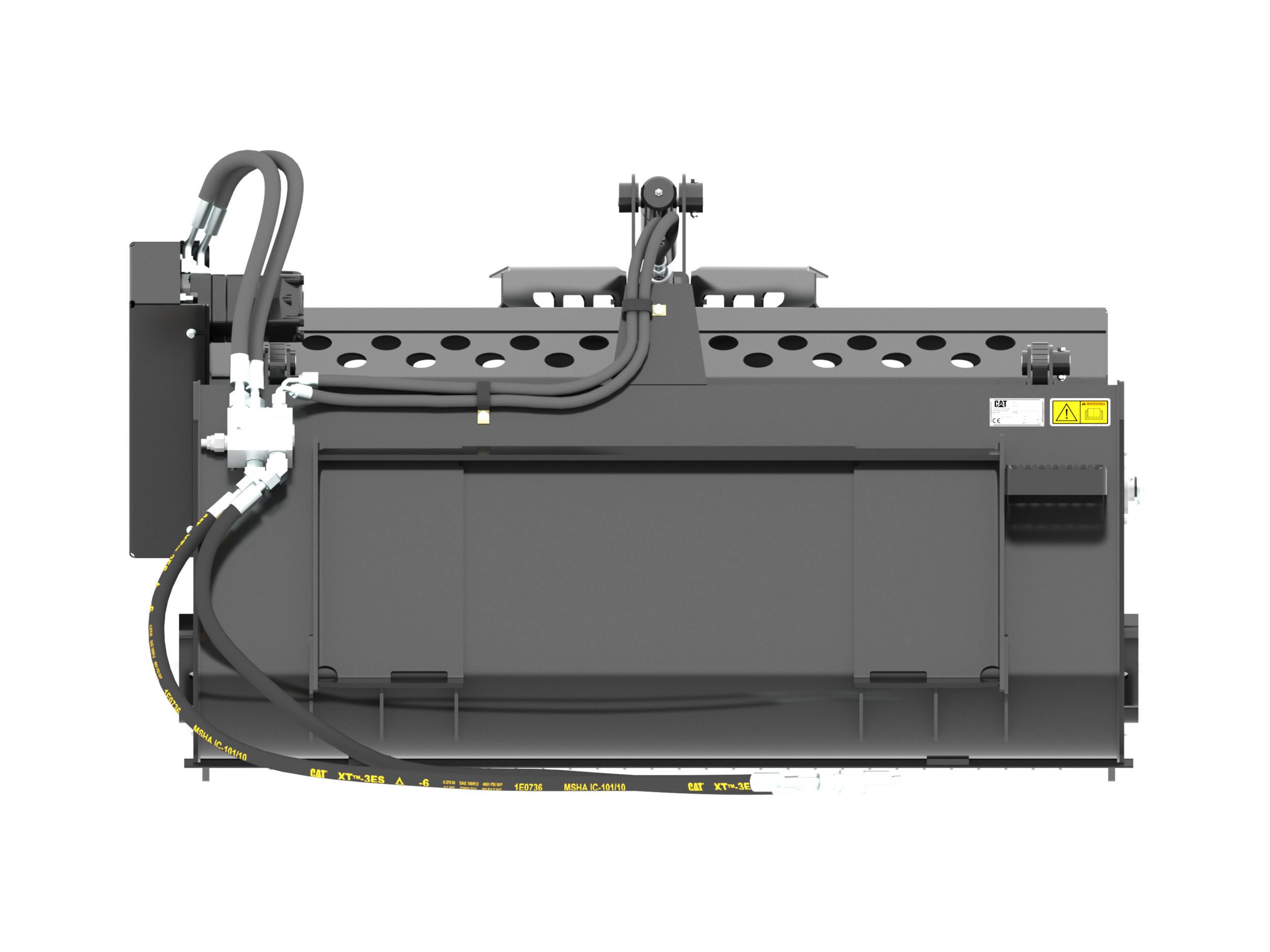

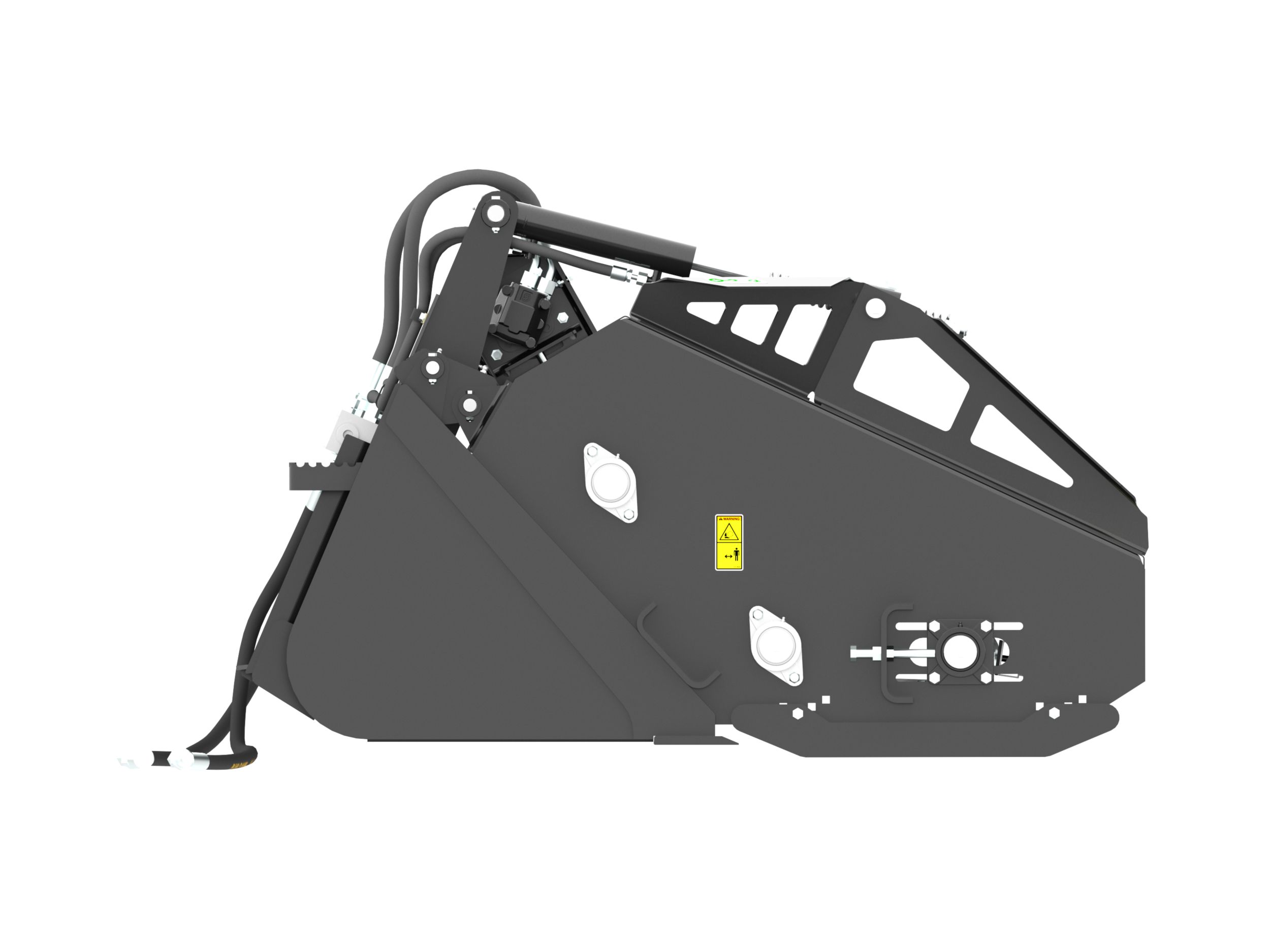

Uses the scarifying action of the hardened teeth to pulverize, aerate, level and condition the soil, while collecting and depositing rock and debris in the integrated hopper bucket for quick removal.

Designed to operate with the loader traveling in reverse, leaving the soil finely groomed with minimal tire compaction.

Chain reduction drive system and steel teeth are built for maximum strength and durability in the toughest soil conditions.

Quick dumping capability is accomplished with a poppet check valve that stops flow to the hydraulic motor and directs flow to the rake head cylinder. Once the hopper bucket is full, simply reverse flow to actuate the rake head cylinder and dump the bucket.

Bolt-on conveyor tubes for easy replacement and serviceability.