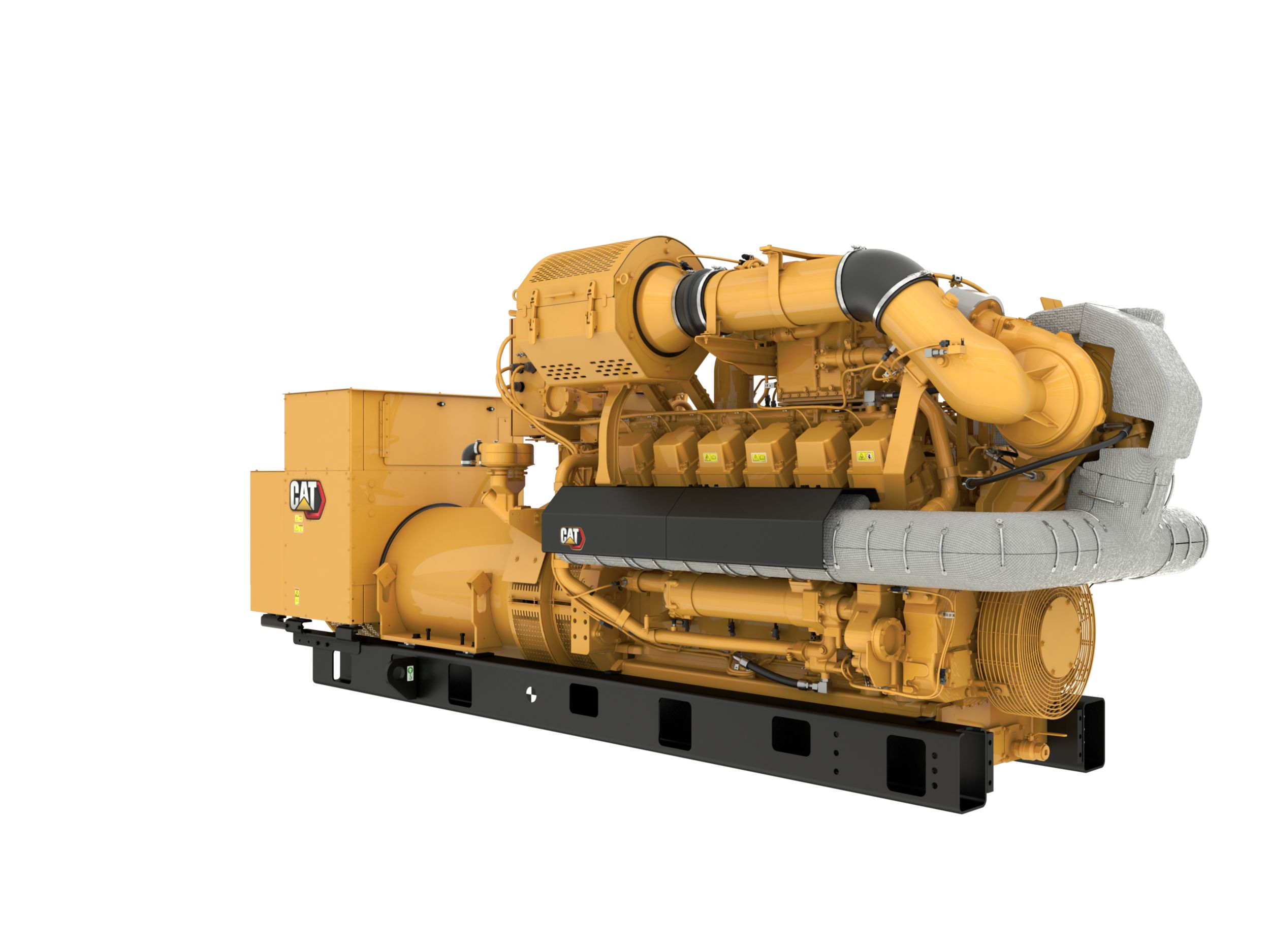

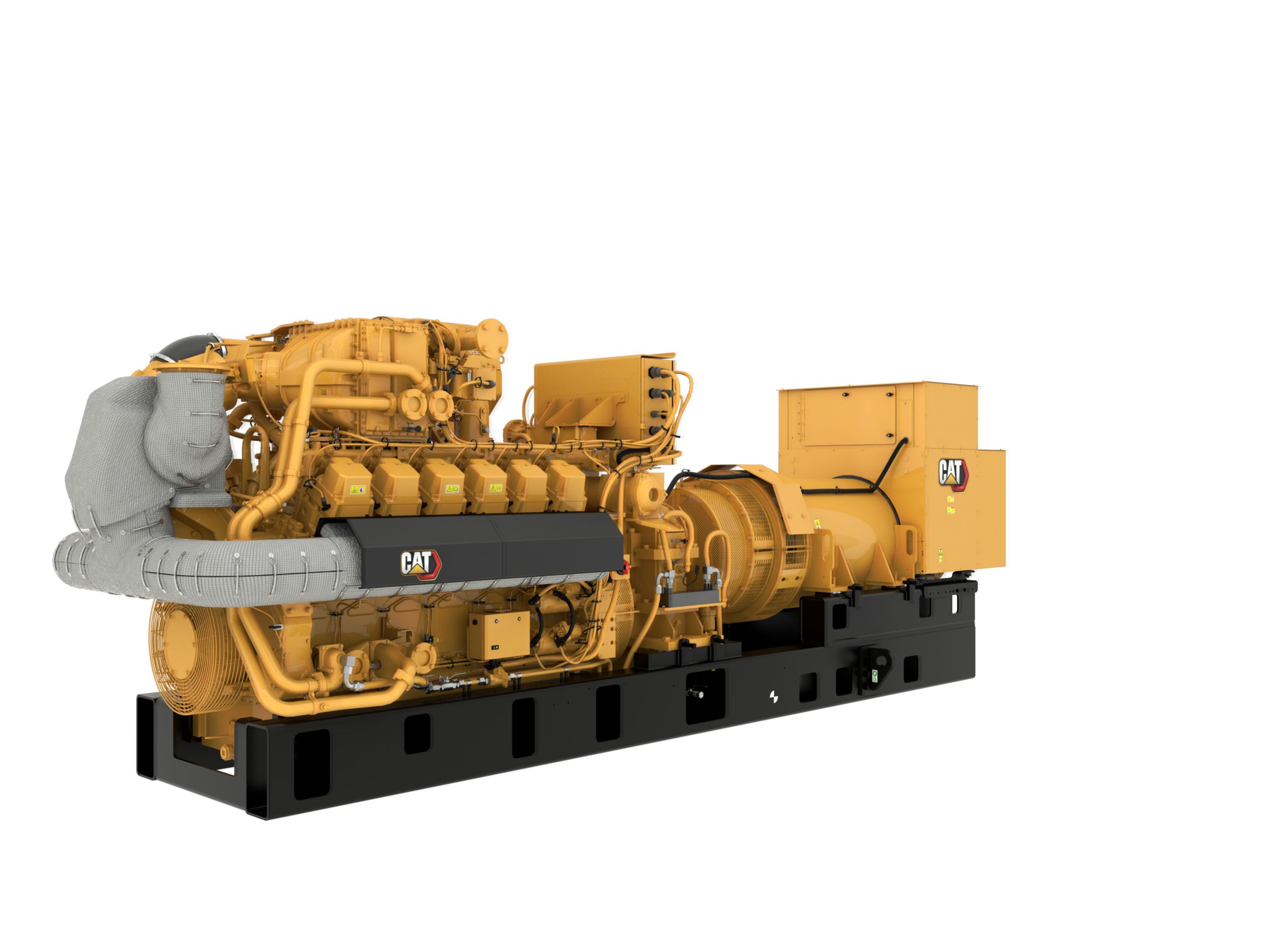

G3512H | 1061kW-1515kW Gas Generator

CHP

CHP G3500H Gas Generator Set Series

G3500H Gas Generator Set SeriesContact Us For Price

SPECS SUMMARY

| Continuous Rating | 1515 ekW / 1505 ekW @1.0pf |

| Fuel Type | Natural Gas, Hydrogen Blend (up to 25%) |

| Maximum Electrical Efficiency | 44.90% |

| Frequency | 50 / 60 Hz |

Specifications

| Continuous Rating | 1515 ekW / 1505 ekW @1.0pf |

| Fuel Type | Natural Gas, Hydrogen Blend (up to 25%) |

| Maximum Electrical Efficiency | 44.90% |

| Frequency | 50 / 60 Hz |

| RPM | 1500 rpm |

| Engine Model | G3512H |

| Displacement | 3574 in³ (59 l) |

| Aspiration | TA |

| Bore | 6.7 in (170 mm) |

| Stroke | 8.5 in (215 mm) |

| Length | 223 in (5656 mm) |

| Width | 76 in (1921 mm) |

| Height | 91 in (2308 mm) |

| Dry Weight - Genset | 31085 lb (14100 kg) |

| Governor Type | ADEM A4 |

Benefits and Features

- Robust high speed block design provides prolonged life and lower owning operationg costs

- Designed for maximum performance on low pressure pipeline natural gas and hydrogen mixtures

- Simple open chamber combustion system for reliability and fuel flexibility

- Leading edge technology in ignition system and air/fuel ratio control for lower emission and engine efficiency

- One electronic control module handles all engine functions: ignition, governing, air/fuel ratio control and engine protection

- Designed to match performance and output characteristics of Caterpillar gas engines

- Industry leading mechanical and electrical design

- High efficiency

- User-friendly interface and navigation

- Scalable system to meet a wide range of installation requirement

- Expansion modules and site-specific programming for specific customer requirements

- Meets most worldwide emissions requirements down to 0.5 g/bhp-hr NOx level without aftertreatment

- Field proven in a wide range of applications worldwide

- Fully prototype tested

- Certified torsional vibration analysis available

- Wide range of bolt-on system expansion attachments

- Factory designed and tested

- Flexible packaging options for easy and cost effective installation

- Cat dealers have over 1,800 dealer branch stores operating in 200 countries

- Your local Cat dealer provides extensive post-sale support, including maintenance and repair agreements

Standard Equipment

- Package Mounted Air Cleaner with service indicator

- Jacket water and SCAC thermostats

- 2nd Stage CAT Flange

- ANSI Class 150 JW Connection

- Engine driven pumps for jacket water and aftercooler cooling

- Dedicated customer wiring terminals

- EMCP4.3

- Dry exhaust manifolds insulated and shielded

- Center section cooled turbocharger with Cat flanged outlet

- High efficiency low voltage Cat generator, permanent magnet excitation, digital regulation, IP23 water ingress protection, & form wound construction.

- Electric Starter

- Paint - Caterpillar Yellow except rails and radiators gloss black

- Crankshaft vibration damper and guard

Optional Equipment

- Mounting brackets and piping

- Air cleaner with precleaner

- Remote annunciator

- Frame mounting circuit breaker orientation

- 2500A 3-pole IEC rated circuit breakers

- Rear Mounted Circuit Breaker

- 3000A/3200A/4000A UL100% Rated Masterpact circuit breaker (60 Hz only)

- LSI Long-Time, LSI-P Long-Time, LSIG Long-Time, LSIG-P Long-Time,

- Language Options

- Cable Shroud Location

- Engine failure relay

- Discrete I/O module, 12 digital points, 8 'Form C' relay

- 16 point/32 light annunciator with NFPA99-110/CSA282 configuration

- Empty Upper Box Right/Left

- Local Alarm module

- Synchronization module

- Cat Connect: Ethernet, satellite, or cell telematics

- Local/Remote PC Monitorring

- Right/Left/Rear Extension Box

- Remote radiator for JW and SCAC circuits

- 220V (50Hz), 240V (60Hz), 480V (60Hz) JW heater

- Flexible fitting [305mm x 305mm (12in. X 12in.)] w/ 12 bolt-flanges

- 406mm (16in.) sparking-arresting muffler with companion flange

- Exhaust expander [250mm-329mm (10in-12in)]

- 305mm (12 in.) flange

- Muffler options

- Elbow exhaust

- 1/2" NPT gas train conduit connectors

- 3, 0-100kPag 4-20mA gas train pressure sensors

- Fuel Filter

- Gas knockdown regulators

- Digital Diagnostic tool

- US Aid emblem

- Generator air filter

- Manual voltage control

- Cable access box

- RTD Monitorring

- Bearing temperature detectors

- ADEM A4 4-20mA (0-5V) speed input

- Battery with cables and rack

- 24V Starting motors

- 20A, 24VDC battery charger

- 45A, 24V charging alternator (requires engine driven pumps)

- Jacket water heater

- 60 Hz: USA

- 50 Hz: Germany, Great Britain, Belgium, Romania, Italy, Ireland, Poland, Netherlands, Spain, France, and European Standard