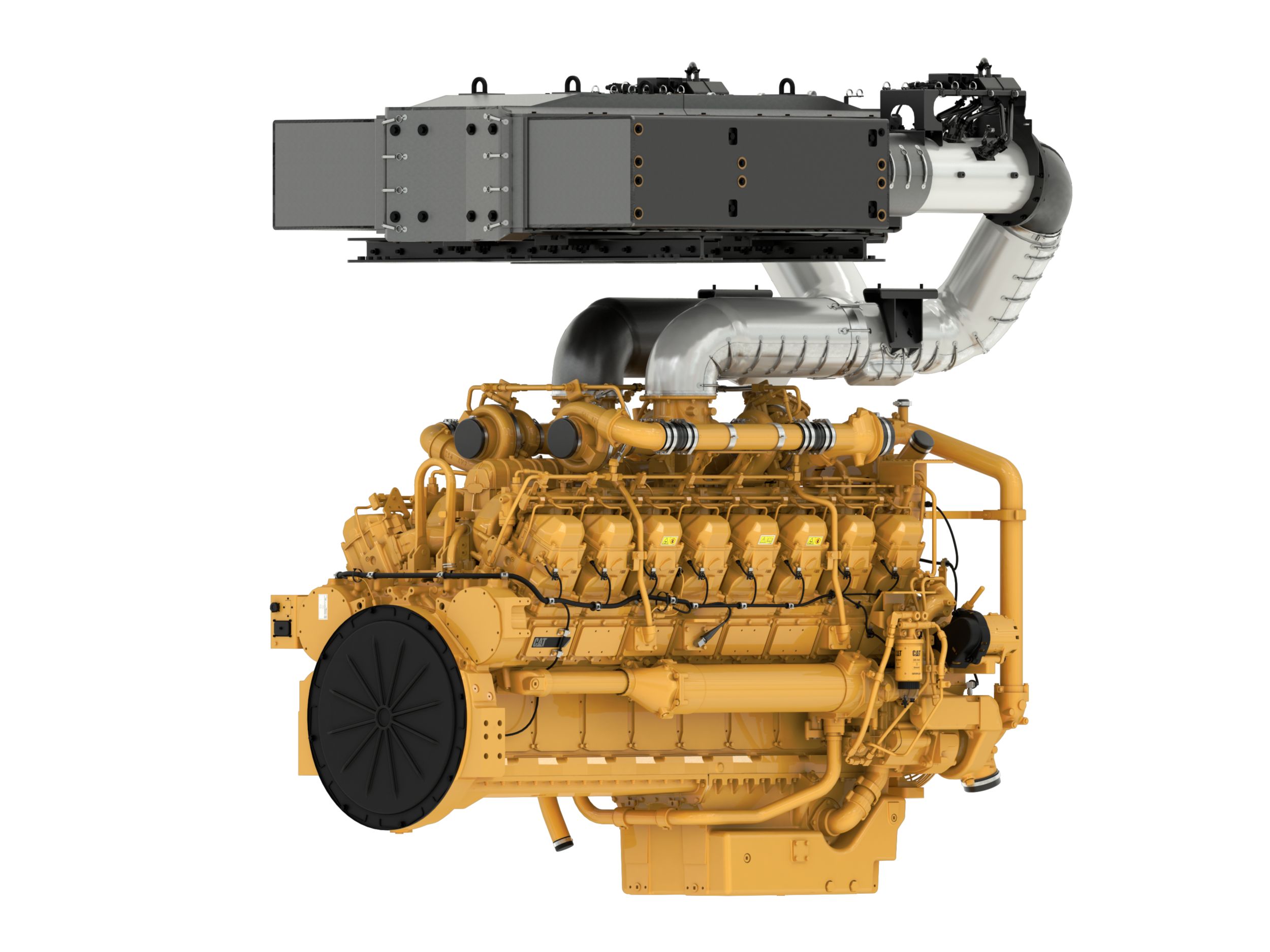

3516E

Contact Us For Price

SPECS SUMMARY

| Maximum Power | 2100 HP (1566 kW) |

| Maximum Torque | 8275 lb-ft @ 1200 rpm (11220 Nm @ 1200 rpm) |

| Emissions | U.S. EPA Tier 4 Final, EU Stage V |

| Rated Speed | 1650 rpm |

The 3516E is certified to meet EU Stage V, U.S. EPA Tier 4 Final, and California Air Regulations Board (CARB) standards, providing a single solution for higher regulated countries and simplifying installations for OEMs.

The 3516E offers unsurpassed performance and durability in a wide array of industries and applications, including shredders, chippers, grinders, bore and drill rigs, and pumps as well as other applications in forestry, general industrial, material handling, and mining.

Specifications

| Maximum Power | 2100 HP (1566 kW) |

| Maximum Torque | 8275 lb-ft @ 1200 rpm (11220 Nm @ 1200 rpm) |

| Emissions | U.S. EPA Tier 4 Final, EU Stage V |

| Rated Speed | 1650 rpm |

| Minimum Power | 2100 HP (1566 kW) |

| Engine Configuration | V-16 |

| Bore | 6.7 in (170 mm) |

| Stroke | 8.5 in (215 mm) |

| Displacement | 4760 in³ (78 l) |

| Compression Ratio | 16.5:1 |

| Aspiration | Turbocharged Aftercooled (TTA) |

| Combustion System | MEUI |

| Rotation from Flywheel End | Counterclockwise |

| Aftertreatment | SCR |

| Length | 122.2 in (3105 mm) |

| Width | 63.6 in (1616 mm) |

| Height | 83 in (2108 mm) |

| Weight - Net Dry - Basic Operating Engine Without Optional Attachments | 18025 lb (8176 kg) |

| Length | 92.5 in (2350 mm) |

| Width | 79.1 in (2008 mm) |

| Height | 31.9 in (809 mm) |

| Weight | 2378 lb (1079 kg) |

Benefits and Features

The A-Rating means the 3516E is able to deliver the engine’s full 2100 hp (1566 kW) @1650 rpm continuously without interruption or load cycling. That’s the type of heavy duty usage that some applications demand and the 3516E delivers it.

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation, and many hours of productive life.

Fuel consumption is optimized to match operating cycles of a wide range of equipment and applications while maintaining low operating costs. Even with the addition of an SCR aftertreatment and the required diesel exhaust fluid, the 3516E costs 1.3% less to operate than the preceeding model

Tier 2 3516C.

Every Cat engine is manufactured to stringent quality standards in order to assure customer satisfaction.

- Scheduled maintenance, including SOSSM sample

- Customer Support Agreements (CSA)

- Caterpillar Extended Service Coverage (ESC)

- Superior dealer service network

- Extended dealer service network through the Cat Industrial Service Distributor (ISD) program

Standard Equipment

- Four turbochargers, centre mounted

- Air-to-Air Aftercooled (ATAAC)

- Electronic engine control

- Two exhaust outlets, 203 mm (8 in) round flange

- Exhaust manifold, dry

- Four turbochargers with watercooled bearings

- Gear-driven centrifugal jacket water pump

- Connections for radiator cooling

- Thermostats and housing

- Flywheel housing, SAE No. 0 or SAE No. 00

- Flywheel, SAE No. 18 or SAE No. 21

- SAE standard rotation

- Fuel filter, LH spin-on type

- Fuel transfer pump

- Electronically controlled unit injectors

- Crankcase breather, top mounted

- Oil cooler

- Oil filler and dipstick, LH

- Oil pump

- Oil filter, LH, spin-on type

- Front sump oil pan, 500-hour change interval

- Paint: Caterpillar yellow, with optional colors available at request

- Vibration damper

- Lifting eyes