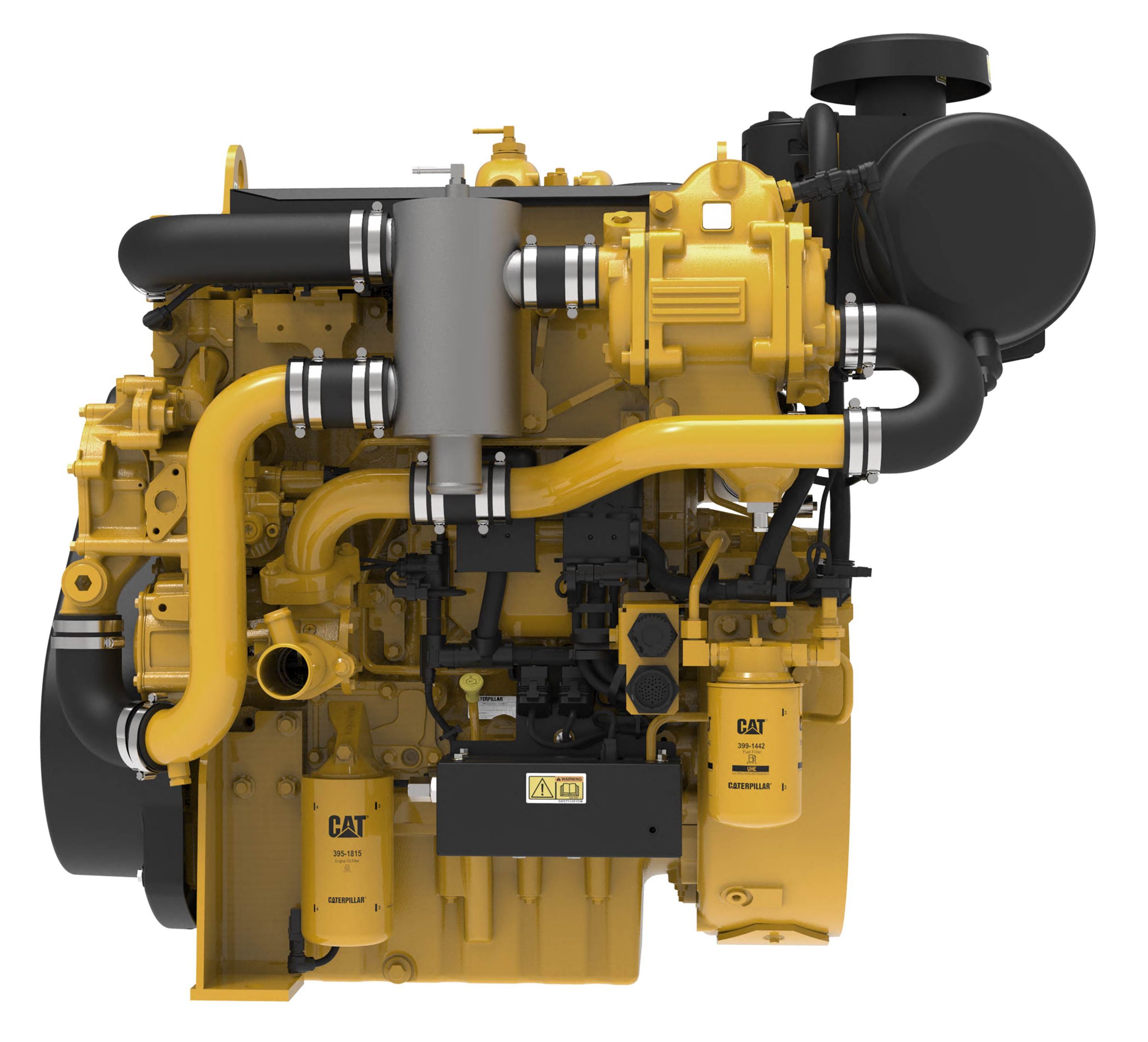

Marine Auxiliary Engines

C4.4 Electronic Control System

C4.4 Electronic Control SystemContact Us For Price

SPECS SUMMARY

| Power Range | 71/81/108/129 bkW @ 1800 rpm, 71/86/108 bkW @ 1500 rpm |

| Length | 33.7 in (856 mm) |

| Configuration | In-line 4, 4-stroke-cycle diesel |

| Height | 40.9 in (1038 mm) |

Specifications

| Power Range | 71/81/108/129 bkW @ 1800 rpm, 71/86/108 bkW @ 1500 rpm |

| Length | 33.7 in (856 mm) |

| Configuration | In-line 4, 4-stroke-cycle diesel |

| Height | 40.9 in (1038 mm) |

| Minimum Width | 30.6 in (778 mm) |

| Emissions | U.S. EPA Tier 3 certified, EU Stage V certified |

| Rated Engine Speed | 1500/1800 rpm |

| Maximum Width | 32 in (814 mm) |

| Bore | 4.13 in (105 mm) |

| Minimum Engine Dry Weight | 1200 lb (544 kg) |

| Stroke | 5 in (127 mm) |

| Maximum Engine Dry Weight | 1278 lb (580 kg) |

| Displacement | 268 in³ (4.4 l) |

| Aspiration | Turbocharged-aftercooled and turbo only aspiration (Turbocharged aspiration only for 65ekW (71bkW)) |

| Governor | Electronic (A5 ECM) |

| Refill Capacity | Lube Oil System w/Oil filter change: 11 L 2.8 gal) |

| Oil Change Interval | 500 hrs |

| Cooling | Heat exchanger, combined circuit keel cooling, or separate circuit keel cooling |

| Flywheel Housing | SAE No. 03 with SAE 11.5 flywheel (126 teeth) |

Benefits and Features

• Simplicity = Reliability

• Configure the engine how you want it, package it yourself

• Compact engine profile with high power density

• Ease of repower with multiple cooling system options: Single circuit keel cooling /Separate circuit keel cooling / Heat exchanger

• Clean, smooth, and quiet operations

• Advanced fuel system provides excellent fuel consumption and low smoke

• Proven core engine design with millions of operating hours

• Fewer maintenance touchpoints and longer service intervals

• Global dealer network for unparalleled support

Standard Equipment

- Gear-driven jacket-water and auxiliary water pumps

- Engine mounted air cleaner and expansion tank

- Integral plate-type oil cooler

- Watercooled exhaust manifold and turbocharger

- Common Rail fuel system

- Electric fuel priming pump

- Internal engine balancing shaft

- Self-tensioning multi-vee belt drive

- Open crankcase ventilation system

- Engine mounted fuel and oil filter

- Engine mounted customer interface and control relays

- 12V or 24V starter motor

Optional Equipment

- MGGP 200 Gauge Panel and interface harness

- Engine shutdown sensors and shutdown controller

- Double wall high pressure fuel lines

- EMCP engine control panel

- Exhaust elbow and bellows

- Rear mounting feet

- Glow plugs

- Jacket water heater

- Jacket water connections (keel cooled)

- S•O•SSM sample points

- Glow plugs