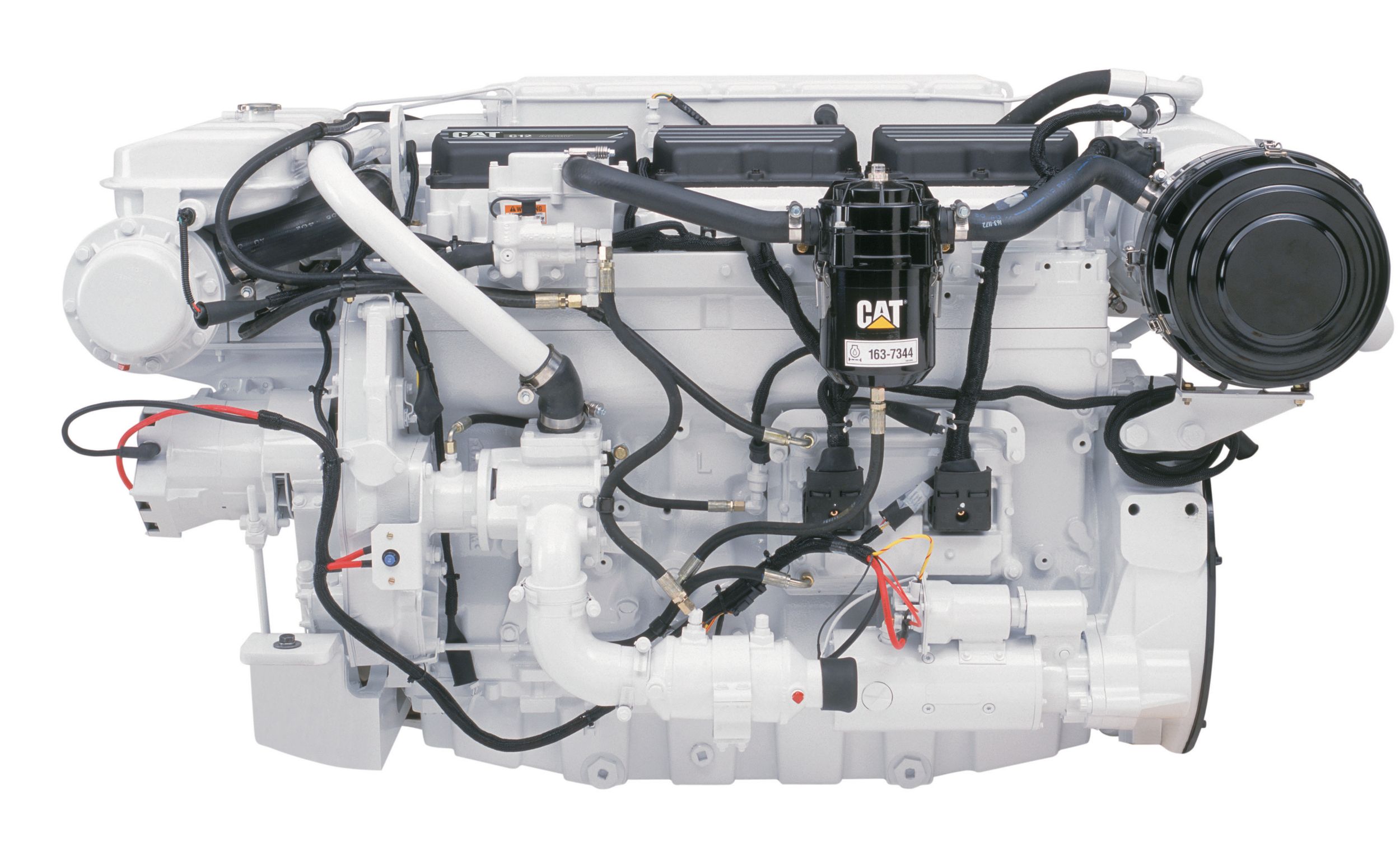

C12 ACERT

Contact Us For Price

SPECS SUMMARY

| Power Range | 660-705 bhp (492-526 bkW) |

| Speed Range | 2300 rpm |

| Emissions | IMO II |

| Aspiration | TA |

Specifications

| Power Range | 660-705 bhp (492-526 bkW) |

| Speed Range | 2300 rpm |

| Emissions | IMO II |

| Aspiration | TA |

| Bore | 5.1 in (130 mm) |

| Stroke | 5.9 in (150 mm) |

| Displacement | 732 in³ (12 l) |

| Rotation from Flywheel End | Counterclockwise |

| Configuration | In-line 6, 4-Stroke-Cycle Diesel |

| Width | 38.1 in (969 mm) |

| Dry Weight | 2588 lb (1174 kg) |

| Length | 62 in (1574 mm) |

| Height | 39.5 in (1005 mm) |

Benefits and Features

Standard Equipment

- Aftercooler - sea water; corrosion resistant, Air Cleaner/Fumes Disposal (closed system), Turbocharger, Jacket Water Cooled

- Electronic governing, Cold mode start strategy, Power compensation for fuel temperature, Programmable low idle, Electronic diagnostics and fault logging, Engine and transmission monitoring (speed, temperature, pressure), Fuel/air ratio control, Emergency stop switch (A&B ratings only)

- Thermostat and housing, Jacket water pump; gear driven, Sea water pump; rubber impeller; self-priming; gear-driven, Integral heat exhanger/expansion tank; removable tube bundle; replaceable copper-nickel tubes, Keel cooling - combined circuit (includes pipe thread flange kit)

- Watercooled Manifold & Turbocharger

- Flywheel; SAE No. 1; 113 teeth, Flywheel housing; SAE No. 1 (10 degree slant pad), SAE standard rotation

- Fuel filer; RH service on Port; LH service on Starboard, Fuel transfer pump, Fuel priming pump, Flexible fuel lines

- Crankcase breather, Oil cooler, Oil filter; spin-on; RH service on Port; LH service on Starboard, Oil filler, Dipstick; RH service on Port; LH service on Starboard, Oil pump; gear driven

- Front support

- Hydraulic pump drive; SAE A; 11 tooth spline, 57 ft-lbs max torque; counterclockwise as viewed from the rear of hte engine looking into the pump drive and turns 1.41 x engine speed, Crankshaft pulley; 345 mm (13.6 in) single groove; 15.88 mm (.63in) width

- Shutdown; electronic; 12 or 24 volt; energized to run

- Vibration damper, Lifting eyes, RH or LH service options, Literature, Variable engine wiring, Upper rear-facing customer wiring connector and ECAP connection, Electronic installation kit (connectors, pins, sockets)

Optional Equipment

- Low Profile Air Inlet Line, Shield (Air Inlet Line)

- Charging Alternators, Voltmeter Guages, Voltmeter Guage Mounting, Alternator Mounting Group

- Sea Water Pump, Coolant Recovery Tank, Flange Kit

- Flexible Fitting, Elbow, Dry Elbow, Watercooled Elbow, Exhaust Connection, Exhaust Outlet Pipe, EXH Outlet Flange, Rain Cap, Muffler

- Fuel Cooler, Fuel Connections, Primary Fuel Filter, Primary Fuel/Water Separator

- OEM Wiring Harness, Engine to Engine Harness, Digital Tachometer, Tachometer Mounting, Magnetic Pickup, RH 4 Hole Instrument Panel, LH 4 Hole Instrument, Marine Power Display System, Marine Power Display Unit (for additional monitoring stations), Marine Power Display Bracket, Wiring Group, Transmission Sensors

- Manual sump pump, Transmission oil cooler

- Vibration Isolators

- Crankshaft Pulley, Front Stub Shaft, Front Stub Shaft & Pulley

- Air Pressure Regulator, Air Start Silencer, Start Switch, Jacket Water Heater, Battery sets (24 volt - dry)

- Wiring Harness Removal, Belt Guard - Alternator, Belt Guard - Alternator Pulley, Filter Cover Kit

- Overseas Preservation, Engine Protective Cover, Storage Preservation, Export Packing