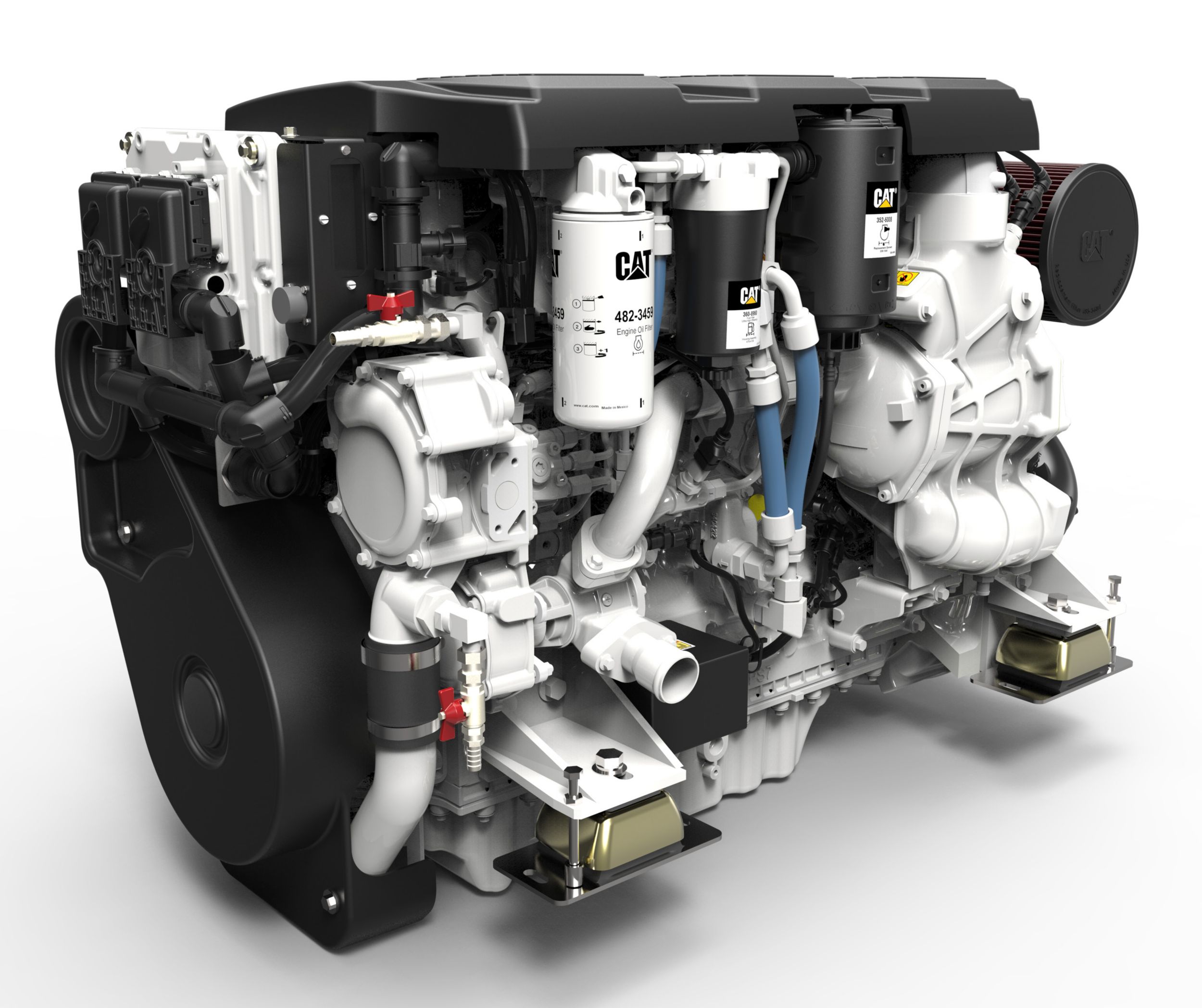

Meet the new C7.1 Commercial Propulsion Engine

Meet the new C7.1 Commercial Propulsion Engine C7.1 Marine Propulsion Engine Walkaround

C7.1 Marine Propulsion Engine WalkaroundContact Us For Price

SPECS SUMMARY

| Power Range | 400 bhp - 500 bhp (298 bkW - 373 bkW) |

| Speed Range | 2900 rpm |

| Emissions | IMO II, U.S. EPA Tier 3, RCD II, China II |

| Rotation from Flywheel End | Counterclockwise |

Specifications

| Power Range | 400 bhp - 500 bhp (298 bkW - 373 bkW) |

| Speed Range | 2900 rpm |

| Emissions | IMO II, U.S. EPA Tier 3, RCD II, China II |

| Rotation from Flywheel End | Counterclockwise |

| Bore | 4.13 in (105 mm) |

| Stroke | 5.31 in (135 mm) |

| Aspiration | Turbocharged, aftercooled |

| Displacement | 428 in³ (7.01 l) |

| Configuration | In-line 6, 4-Stroke-Cycle Diesel |

| Width - Engine | 31.4 in (798 mm) |

| Height | 34.5 in (876 mm) |

| Engine Dry Weight - Approximate | 1676 lb (760 kg) |

| Length - Engine | 43.1 in (1095 mm) |

Benefits and Features

- Common rail fuel system enables optimum combustion and low emissions

- Reduced combustion noise through advanced electronic control

- 12V or 24V electrical system

- Compatible with Cat® displays and electronics

- Closed crankcase ventilation system improves engine room cleanliness

- Gear-driven jacket water pump and sea water pump for superior reliability

- Maintenance free valve train with hydraulic valve lash adjusters

- Self-priming fuel system ensures a smooth start every time

Standard Equipment

- Water cooled turbocharger and exhaust manifold

- Common rail fuel system

- Corrosion resistant sea water aftercooler

- Closed crankcase ventilation system

- Starter motors - 12V or 24V

- Fuel cooler

- Integral engine oil cooler

- Vibration damper and guard

- Electric fuel priming pump

- Self-tensioning multi-vee alternator drive belt

- Gear driven sea water pump (rubber impeller)

- Fin and tube type jacket water heat exchanger

- Front and rear engine mounting brackets

Optional Equipment

- Alternators - 24V 140 amp - 12V 175 amp

- Transmission gear oil cooler (engine mounted)

- Instrument Panels

- Glow plugs

- Jacket water heater

- 6" water cooled exhaust elbow

- Isolation mounts

- Primary fuel filter/water separator (remote mount)

- Selection of factory-fitted marine transmissions and oil hoses

- Cabin heater (calorifier) connections

- Triple groove PTO pulley (crankshaft mounted)

- Flexible fuel hoses

- Right-hand and high level left hand oil dipsticks