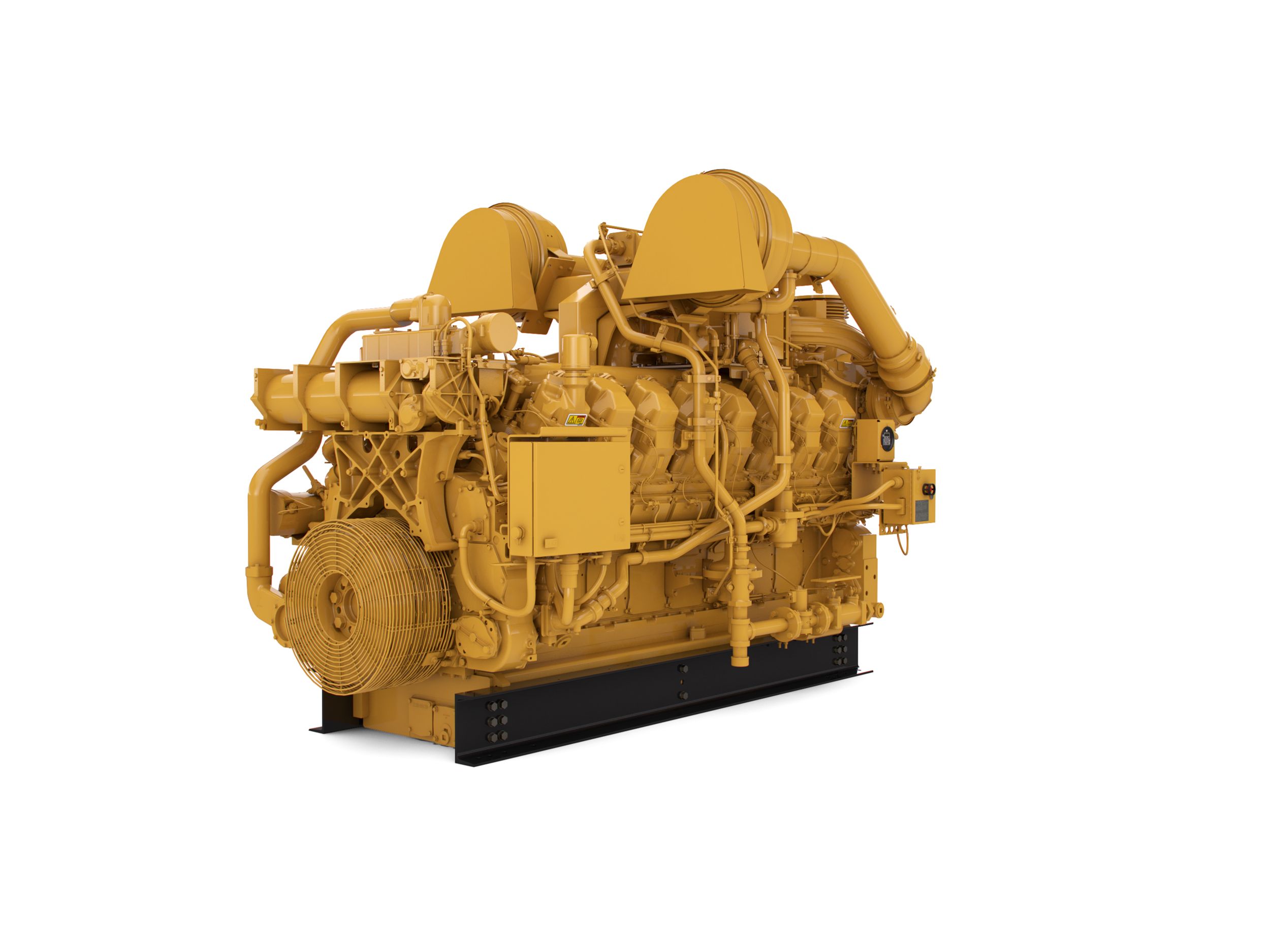

G3516J

Contact Us For Price

SPECS SUMMARY

| Maximum Rating | 1380 BHP (1029 bkW) |

| Emissions | U.S. EPA Spark Ignited Stationary NSPS emissions |

| Displacement | 4211 in³ (69 l) |

| Minimum Rating | 1380 BHP (1029 bkW) |

Specifications

| Maximum Rating | 1380 BHP (1029 bkW) |

| Emissions | U.S. EPA Spark Ignited Stationary NSPS emissions |

| Displacement | 4211 in³ (69 l) |

| Minimum Rating | 1380 BHP (1029 bkW) |

| Aspiration | Turbocharged-2 Stage aftercooled |

| Oil Change Interval | 1000 hrs |

| Stroke | 7.5 in (190 mm) |

| Bore | 6.7 in (170 mm) |

| Combustion | Lean Burn |

| Governor | Electronic (ADEM A3) |

| Lube Oil System | 423 L (112 gal) |

Benefits and Features

- Proven reliability and durability - Ability to burn a wide spectrum of gaseous fuels - Robust diesel strength design prolongs life and lowers owning and operating costs - Broad operating speed range

Meets U.S. EPA Spark Ignited Stationary NSPS Emissions for 2010

Lean-burn engines operate with large amounts of excess air. The excess air absorbs heat during combustion reducing the combustion temperature and pressure, greatly reducing levels of NOx. Lean-burn design also provides longer component life and excellent fuel consumption.

ADEM A3 control system providing integrated ignition, speed governing, protection, and controls, including detonation-sensitive variable ignition timing. ADEM A3 has improved: user interface, display system, shutdown controls, and system diagnostics.

Side covers on block allow for inspection of internal components

Large variety of factory-installed engine attachments reduces packaging time

Every engine is full-load tested to ensure proper engine performance.

GERP is a web-based program designed to provide site performance capabilities for Cat® natural gas engines for the gas compression industry. GERP provides engine data for your site's altitude, ambient temperature, fuel, engine coolant heat rejection, performance data, installation drawings, spec sheets, and pump curves.

More than 2,200 dealer outlets Cat factory-trained dealer technicians service every aspect of your petroleum engine Cat parts and labor warranty Preventive maintenance agreements available for repairbefore- failure optionsS•O•SSM program matches your oil and coolant samples against Caterpillar set standards to determine: - Internal engine component condition - Presence of unwanted fluids - Presence of combustion by-products - Site-specific oil change interval

Over 60 years of natural gas engine production Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products. - Cast engine blocks, heads, cylinder liners, and flywheel housings - Machine critical components - Assemble complete engine

Standard Equipment

- Axial flow air cleaners

- Single element canister type with service indicator

- Two-stage charge air cooling system

- Engine cooling and charge air cooling thermostats

- Watercooled exhaust manifolds

- Dry Turbocharger housings

- Water-cooled exhaust elbow

- SAE No. 00 flywheel housing

- SAE standard rotation

- SAE No. 21 Flywheel

- 7-40 psig gas supply

- Electronic fuel metering valve

- Gas pressure regulator

- Gas shutoff valve

- Fuel System

- Remote-mounted Advisor control panel

- Interconnect harness

- Crankcase breather — top mounted

- Oil cooler

- Oil filter — RH

- Oil pan — shallow

- Oil sampling valve

- Turbo oil accumulator

- Rails

- Electronic shutoff system

- Gas shutoff valve

- Paint — Cat yellow

- Crankshaft vibration damper and guard

- Front lower LH accessory drive

- Front housing, two sided

Optional Equipment

- Remote air inlet adapters

- Rain Shield

- CSA Alternator (24V, 65A)

- Flexible fittings

- Elbows

- Flange

- Mufflers

- Fuel filter

- Oil bypass filter

- Deep sump oil pan

- Air prelube pump

- Lubricating oil

- Oil pan drain

- Front stub shaft

- Explosion relief valves, status control box interconnect wiring harness

- 90 psi starter

- 150 psi starter

- EEC DOI certification