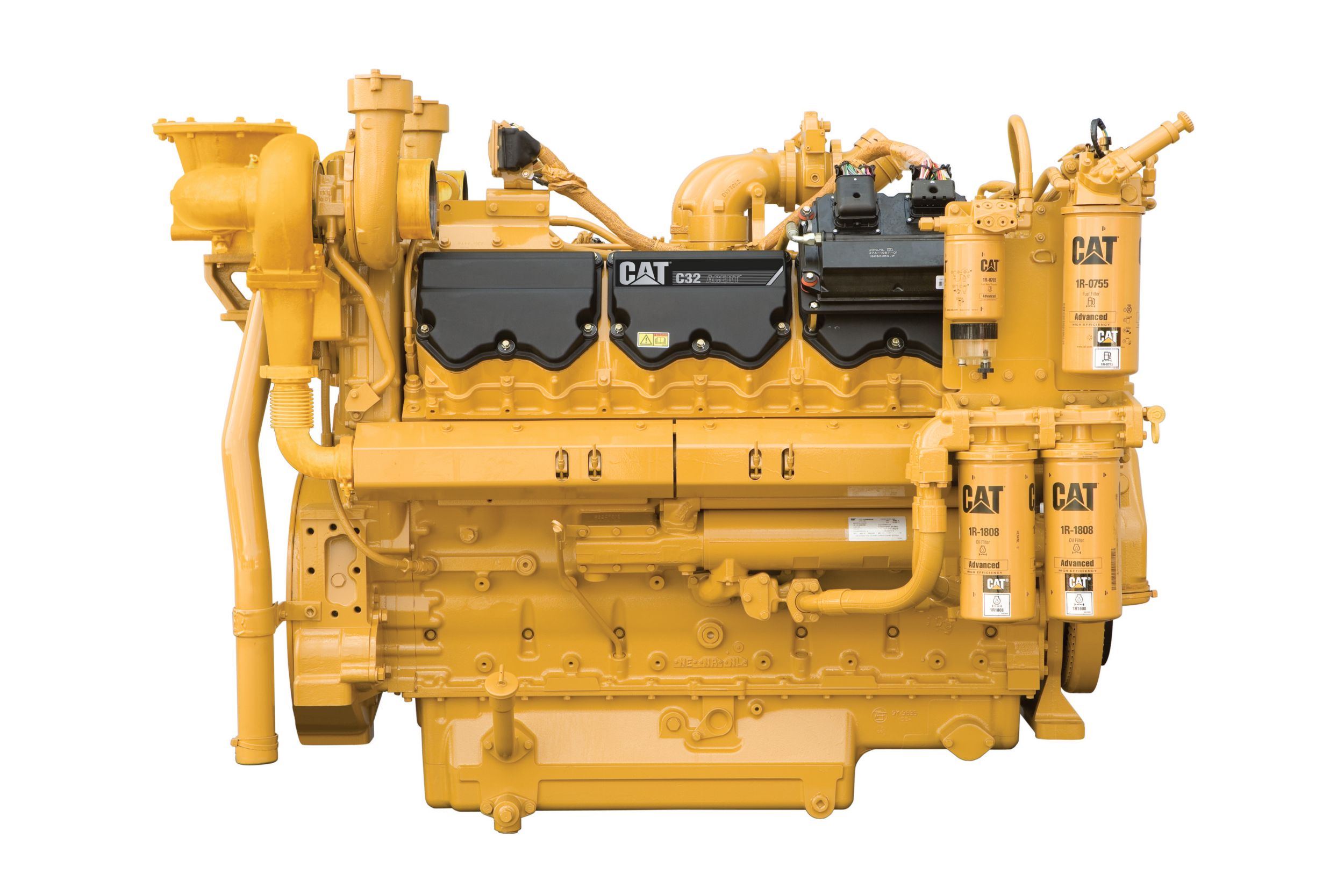

C32 ACERT™

Contact Us For Price

SPECS SUMMARY

| Maximum Rating | 1500 BHP (1119 bkW) |

| Emissions | U.S. EPA Non-road Tier 2 |

| Displacement | 1953 in³ (32 l) |

| Minimum Rating | 800 BHP (597 bkW) |

Specifications

| Maximum Rating | 1500 BHP (1119 bkW) |

| Emissions | U.S. EPA Non-road Tier 2 |

| Displacement | 1953 in³ (32 l) |

| Minimum Rating | 800 BHP (597 bkW) |

| Bore | 5.7 in (145 mm) |

| Stroke | 6.4 in (162 mm) |

| Rated Speed | 2100 r/min (1800 r/min) |

| Aspiration | Turbocharged-Aftercooled |

| Governor and Protection | ADEM A3 |

| Engine Weight - Net Dry | 5040 lb (2286 kg) |

| Minimum Cooling System - Engine Only | 14.5 gal (US) (55 l) |

| Rotation from Flywheel End | Counterclockwise |

| Oil Change Interval | 250 |

| Flywheel and Flywheel Housing | SAE No. 0 or SAE No. 1 |

| Flywheel Teeth | 136 (SAE 0), 113 (SAE 1) |

| Length | 75.5 in (1918 mm) |

| Width | 85 in (1473 mm) |

| Height | 52 in (1321 mm) |

Benefits and Features

- Proven reliability and durability- Robust diesel strength design prolongs life and lowersowning and operating costs- Broad operating speed range- High power density — lightweight engine for weightsensitive applications- PTO drive options provide flexible access to auxiliarypower for pumps and other needs

ADEM A4 engine management system integrates speedcontrol, air/fuel ratio control and ignition/detonationcontrols into a complete engine management systemwith integrated digital ignition, engine protection andmonitoring.

Caterpillar has a full line of engine-transmission packagesthat can be fully integrated with your axle, hydraulics, andoperator interface. Cat®transmissions deliver continuousoperation under full load, smooth shifting at any speed,and maximum up time, with unmatched durability andeasy maintenance

For any petroleum application, trust Caterpillar to meetyour exact needs with a factory custom package. Catengines, generators, enclosures, controls, radiators,transmissions — anything your project requires — can becustom designed and matched to create a one-of-a kindsolution. Custom packages are globally supported andare covered by a one-year warranty after startup.

Large variety of factory-installed engine attachmentsreduces packaging time

Every engine is full-load tested to ensure proper engineperformance.

More than 2,200 dealer outletsCat factory-trained dealer technicians service everyaspect of your petroleum engineCat parts and labor warrantyPreventive maintenance agreements available for repairbefore-failure optionsS•O•SSMprogram matches your oil and coolant samplesagainst Caterpillar set standards to determine:- Internal engine component condition- Presence of unwanted fluids- Presence of combustion by-products- Site-specific oil change interval

Ownership of these manufacturing processes enablesCaterpillar to produce high quality, dependable products.- Cast engine blocks, heads, cylinder liners, and flywheelhousings- Machine critical components- Assemble complete engine

For all your petroleum power requirements, visit www.cat.com/oilandgas

Standard Equipment

- Quad turbocharger — 3 cylinder exhaust to each turbo

- Connections configured for ATAAC (Air-to-Air-Aftercooled)or remote heat exchanger

- ADEM A4 electronic control module

- Electronic governing, PTO speed control

- Customer programmable ratings

- Cold mode start strategy

- Automatic altitude compensation

- Automatic fuel temperature compensation

- Programmable low and high idle, and top engine speedlimit

- Electronic diagnostics and fault logging

- Engine monitoring system

- SAE J1939 broadcast (diagnostic and engine status)

- Gear-driven centrifugal jacket water pump — RH

- Integrated thermostat and housing

- Engine oil cooler

- Optional installed transmission oil cooler

- Exhaust manifold — dry

- Two vertical exhaust outlets (front and rear)

- MEUI

- Fuel priming pump

- Fuel transfer pump

- Primary and secondary fuel filter — RH configured forremote mounting (installed RH on shipping plate)

- SAE No. 0 or SAE No. 1 flywheel iron housing

- SAE No. 0 or SAE No. 1 flywheel

- Optional transmission adapter

- Crankcase breather

- Oil filter — RH standard, optional LH or remote mountservice

- Oil level gauge — RH standard, optional LH or dualservice

- Oil filler — RH standard, optional LH or dual service

- Shallow oil pan, rear sump

- Trunnion front support

- Vertical and horizontal pads on rear flywheel housing

- 24V electronic

- Engine overspeed with optional air shut-offs withindicators

- Low engine oil pressure

- Fuel filter restriction

- Fuel temperature

- High engine coolant temperature

- Low engine coolant temperature

- Vibration damper and optional guard

- Lifting eyes

- Optional customer wiring connector

- Service tool connector

- Paint — Cat yellow

Optional Equipment

- Air cleaner

- Air inlet adapters

- Turbocharger outlet adapters

- Air lines

- Battery chargers

- Charging alternators

- Alternator mounting

- Circuit breakers and mountings

- Dry charge coolant conditioners

- Thermostat housing

- Coolant level sensor

- Radiator

- Blower fans

- Suction fans

- Fan adapters

- Fan drives

- IMO certifications

- Elbows

- Mufflers

- Electric fuel priming pump

- Customer management device

- Interconnect harness

- Gauges and instrument panels

- Oil pans

- Oil service side

- Oil level gauge

- Oil filters

- Lubricating oils

- Structural steel base

- Engine support — front

- Engine support — rear

- Auxiliary drive

- Damper pulley

- Hydraulics gear pumps

- Mechanical shutoffs

- Solenoid shutoffs

- Electric starting motors – 12V, 24V

- Battery sets – 24V

- Battery cable

- Battery rack

- Starting aids

- Transmissions water lines

- Transmissions cooler