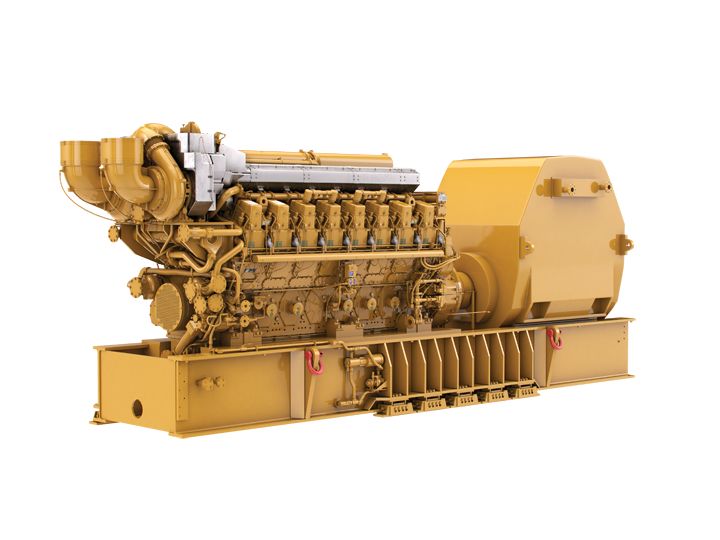

C280-12

Contact Us For Price

SPECS SUMMARY

| Minimum Rating | 4640 kV·A (3460 ekW) |

| Maximum Rating | 5444 kV·A (4060 ekW) |

| Emissions | IMO Tier II/EPA Marine Tier 2 |

| Displacement | 13546 in³ (222 l) |

Specifications

| Minimum Rating | 4640 kV·A (3460 ekW) |

| Maximum Rating | 5444 kV·A (4060 ekW) |

| Emissions | IMO Tier II/EPA Marine Tier 2 |

| Displacement | 13546 in³ (222 l) |

| Lube Oil System - Refill | 339 gal (US) (1283 l) |

| Width | 101.1 in (2568 mm) |

| Height | 156.4 in (3973 mm) |

| Length | 319.9 in (8125 mm) |

| Stroke | 11.8 in (300 mm) |

| Oil Change Interval | 1000 h (1000 h) |

| Engine Control | Dual ADEM™ A4 |

| Fuel System | EUI |

| Generator Set Control | Cat® Alarm and Protection System |

| Aspiration | Turbocharged-Aftercooled |

| Bore | 11 in (300 mm) |

| Weight | 124561 lb (56500 kg) |

| Cooling System - Engine | 329 gal (US) (1245 l) |

Benefits and Features

For any petroleum application, trust Caterpillar to meet your project needs with custom factory generator sets and mechanical packages. Cat engines, generators, controls, radiators, and transmissions can be custom designed and matched in collaboration with our local dealers to create unique solutions. Custom packages are globally supported and are covered by a one year warranty after startup.

Large variety of factory-installed engine attachments increases application flexibility and reduces installation time. Testing • Every unit is full-load tested to ensure proper package performance • Full range of factory tests and reports are available including performance, torsional-vibration analysis, fuel consumption, engine, and generator special tests

• Every unit is full-load tested to ensure proper package performance • Full range of factory tests and reports are available including performance, torsional-vibration analysis, fuel consumption, engine, and generator special tests

- More than 2,200 dealer outlets - Cat factory-trained dealer technicians service every aspect of your Cat petroleum product - Worldwide parts availability, service, and warranty - Preventive maintenance agreements available for repairbefore- failure opti

- More than 2,200 dealer outlets - Cat factory-trained dealer technicians service every aspect of your Cat petroleum product - Worldwide parts availability, service, and warranty - Preventive maintenance agreements available for repairbefore- failure options - SOSSM program matches your oil and coolant samples against Caterpillar set standards to determine: Internal engine component condition Presence of unwanted fluids Presence of combustion by-products Site-specific oil change interval

• C280 engines incorporate over 20 years of proven component reliability and durability from 3600 engines • Large field population in offshore applications provides proven performance, reliability, durability, and established worldwide product support network

For all your petroleum power requirements, visit www.cat.com/oilandgas

Standard Equipment

- The engine is a turbocharged, aftercooled, four-strokecycle- diesel, electronic unit injection engine with a 280 mm (11 in) bore by 300 mm (11.8 in) stroke. SAE standard rotation is counterclockwise as viewed from the rear of engine flywheel.

- GL and CCS approved IMO certificate — includes statement of compliance or Engine International Air Pollution Prevention (EIAPP) certificate, supplied by the Recognized Organization (RO) where available, and technical file to be kept on board per IMO regulations.

- ABS, BV, CCS, DnV, GL, LRS

- Spray shielding to meet SOLAS regulations for flammable fluids

- Declaration of Incorporation for EU Machinery Safety

- Directive and EU Low Voltage Safety Directive

- Fresh water aftercooler, corrosion resistant coated (air side)

- Air inlet shutoff

- Turbochargers (2), rear-mounted, oil lubricated

- 90° adapter and straight adapters for air inlet to turbocharger

- Air cleaners

- Air cleaners with Cat dry paper filter elements (approximately 99.9% efficient at filtering SAE fine dust)

- Dual Cat ADEM A4 electronic engine control module with electronic unit injector fuel system, rigid wiring harness (10 amp 24V power required to drive electronic engine control modules), direct rack control

- Gear-driven jacket water (JW) pump

- Gear-driven separate-circuit aftercooler/oil cooler (AC/OC) pump

- Front-mounted water connections: JW and AC/OC, 6" ANSI

- Jacket Water Thermostat Options:

- AC/OC Thermostat Options:

- Expansion Tank Options:

- Dry, gas tight exhaust manifold

- Dual turbocharger, rear-mounted

- Dual wastegate; hard shielding - SOLAS compliant

- Exhaust manifold shields

- Distillate fuel (requires viscosity ranging from 1.4 cSt to 20 cSt at 38°C); fuel pump, gear-driven; fuel transfer pump (mounted on left-hand side); duplex fuel filters, rear-engine-mounted; electronically controlled unit injectors

- ; crankcase breathers, top-mounted; turbochargers (2), front-mounted, oil lubricated

- Centrifugal oil filters and lines with single shutoff - RH mounted on cylinder block inspection covers, serviceable with the engine running

- Oil pump, gear-driven

- Oil filler and dipstick - located in base integrated tank

- Oil pressure regulating valve

- Duplex oil filter - accessory module mounted

- Off engine mounted oil cooler - DTO quote required for package connections

- Base integrated tank - DTO required

- Electric continuous prelube pump

- Redundant prelube with continuous electric prelube

- Intermittent air prelube backup

- Flywheel and damper guards

- Crankcase explosion relief valves

- Cat Alarm and Protection System Features:

- TDI dual air starting motors, LH rear

- Shutoff valve

- Two integrated relay valves with built-in screen #40 mesh and solenoid

- Air pressure sensor, monitored by Cat Alarm and Protection System - requires customer wiring

- Maximum operating (dynamic) pressure: 10 bar (150 psi)

- Maximum static pressure: 14 bar (200 psi)

- 3-inch ANSI flange customer connection; requires customer-provided 3-inch supply air line from receiver or regulator to air starter and flex connection; if regulator is used, Cv of 40 or greater is required

- Pressure reducing valve

- Design-To-Order (DTO) base

- Generator panel

- Torsional coupling

- Engine barring device options:

Optional Equipment

- Soot filter

- Air cleaner support bracket

- Jacket water heater

- ANSI connection adapters

- Flexible exhaust fittings

- Weld flanges

- Manual fuel priming pump

- Duplex primary fuel strainer

- Lube oil heater

- Cylinder pressure relief valve

- Spray shielding

- Oil mist detector

- Vertically-restrained vibration isolators and weld plates

- Accessory module - Front mounted for mounting expansion tank, heat exchanger, instrument panel, annunciator panel, alarm and shutdown contactors, and fuel strainer

- Engine testing — certified dynamometer test, fuel consumption test, rated speed performance test, overload test, minimum power setting, peak firing pressure test, turbo work certificates, crankshaft work certificates, standard and project-specific witness testing

- Spare parts kit

- Engine lifting eyes

- Project-specific installation drawings

- Electrical schematics and P&ID drawings