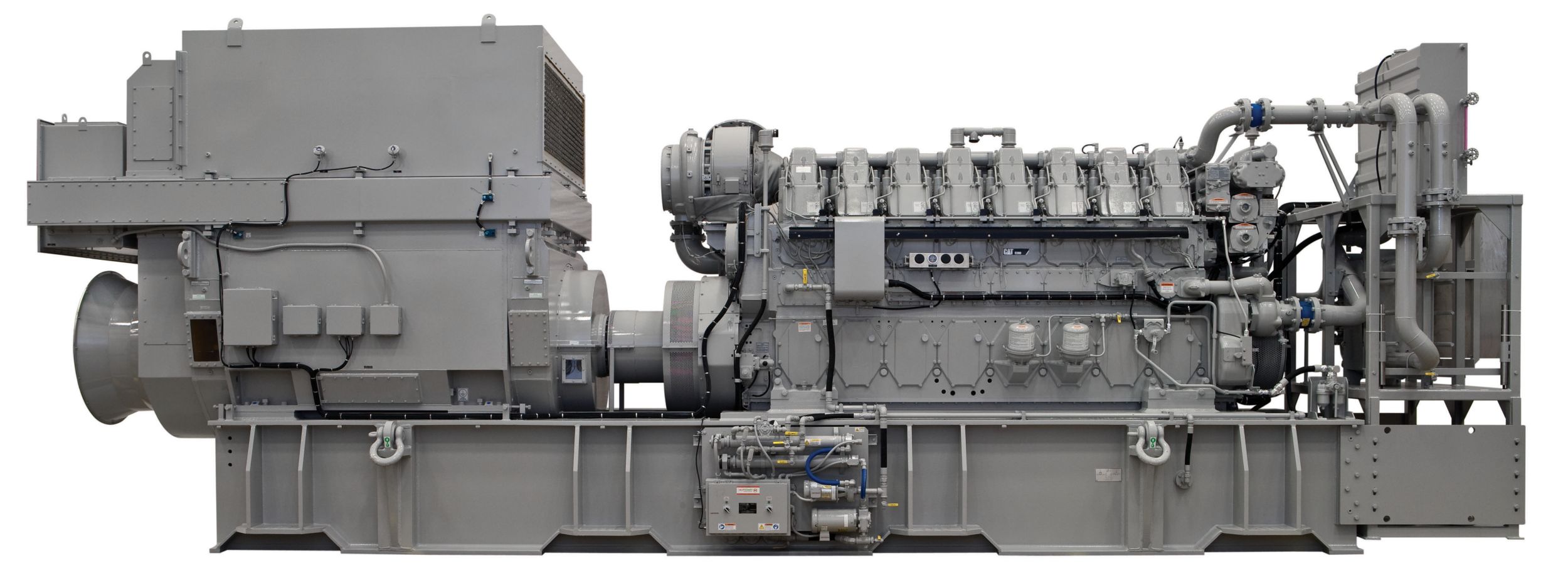

C280-8

Contact Us For Price

SPECS SUMMARY

| Minimum Rating | 3084 kV·A (2300 ekW) |

| Maximum Rating | 3634 kV·A (2710 ekW) |

| Emissions | IMO Tier II/EPA Marine Tier 2 |

| Fuel System | EUI |

Specifications

| Minimum Rating | 3084 kV·A (2300 ekW) |

| Maximum Rating | 3634 kV·A (2710 ekW) |

| Emissions | IMO Tier II/EPA Marine Tier 2 |

| Fuel System | EUI |

| Cooling System - Engine | 140 gal (US) (530 l) |

| Width | 91.6 in (2326 mm) |

| Height | 134.1 in (3406 mm) |

| Length | 320.5 in (8140 mm) |

| Bore | 11 in (280 mm) |

| Stroke | 11.8 in (300 mm) |

| Engine Control | Electronic ADEM™ A3 |

| Aspiration | Turbocharged-Aftercooled |

| Generator Set Control | Generator Monitoring System (GMS) |

| Weight | 108027 lb (49000 kg) |

| Oil Change Interval | 1000 h (1000 h) |

| Displacement | 9031 in³ (148 l) |

| Lube Oil System - Refill | 289 gal (US) (1094 l) |

Benefits and Features

• Cat C280 engines incorporate more than 20 years of proven component reliability and durability from 3600 engines

- Offshore drilling package provides single lift handling- Caterpillar warranty for all packaged components- Includes most ancillaries, ready-to-run package- Easy to handle and install, few shipped-loose parts

For any petroleum application, trust Caterpillar to meetyour project needs with custom factory generator setsand mechanical packages. Cat engines, generators,controls, radiators, and transmissions can be customdesigned and matched in collaboration with our localdealers to create unique solutions. Custom packagesare globally supported and are covered by a one-yearwarranty after startup.

Large variety of factory-installed engine attachmentsincreases application flexibility and reduces installationtime.Testing• Every unit is full-load tested to ensure proper packageperformance• Full range of factory tests and reports are availableincluding performance, torsional-vibration analysis, fuelconsumption, engine, and generator special tests

• Every unit is full-load tested to ensure proper packageperformance• Full range of factory tests and reports are availableincluding performance, torsional-vibration analysis, fuelconsumption, engine, and generator special tests

More than 2,200 dealer outletsCaterpillar factory-trained dealer technicians serviceevery aspect of your Cat engineCaterpillar parts and labor warrantyPreventive maintenance agreements available for repairbefore-failure optionsS•O•SSM program matches your oil and coolant samplesagainst Caterpillar set standards to determine:- Internal engine component condition- Presence of unwanted fluids and combustionby-products- Site-specific oil change interval

• C280 engines incorporate over 20 years of provencomponent reliability and durability from 3600 engines• Large field population in offshore applications providesproven performance, reliability, durability, andestablished worldwide product support network

Visit www.cat.com/oilandgas to learn more.

- Electronic Unit Injection (EUI) fuel system providesoptimized combustion at any load- Lower specific fuel consumption at part load- Reduced transient smoke and emissions

Standard Equipment

- The engine is a turbocharged, aftercooled, four-strokecycle-diesel, electronic unit injection engine with a280 mm (11 in) bore by 300 mm (11.8 in) stroke. SAEstandard rotation is counterclockwise as viewed from therear of engine flywheel.

- GL and CCS approved IMO certificate — includesstatement of compliance or Engine International AirPollution Prevention (EIAPP) certificate, supplied by theRecognized Organization (RO) where available, andtechnical file to be kept on board per IMO regulations.

- ABS, BV, CCS, DnV, GL, LRS

- Spray shielding to meet SOLAS regulations for flammablefluids

- Declaration of Incorporation for EU Machinery Safety

- Directive and EU Low Voltage Safety Directive

- Fresh water aftercooler, corrosion resistant coated (airside)

- Air inlet shutoff

- Turbocharger, rear-mounted, oil lubricated

- Single Cat ADEM A3 electronic engine control module withelectronic unit injector fuel system, rigid wiring harness(10 amp 24V power required to drive electronic enginecontrol modules)

- Gear-driven jacket water (JW) pump

- Gear-driven separate-circuit aftercooler/oil cooler (AC/OC) pump

- Engine coolant water drains

- Dry, gas tight exhaust manifold

- Distillate fuel (requires viscosity ranging from 1.4 cStto 20 cSt at 38°C)

- Fuel pump, gear-driven

- Fuel transfer pump (mounted on left-hand side)

- Duplex fuel filters, rear-engine-mounted

- Electronically controlled unitinjectors

- Centrifugal oil filters with single shutoff, service-side enginemounted on cylinder block inspection covers (includesinstalled oil lines and single shutoff valve), filters centrifugebypass oil from the main lubricating oil pump (can be servicedwith the engine running)

- Oil filler and dipstick

- Oil pressure regulating valve

- Dry engine-mounted sump system that gravity feeds intobase assembly integral sump

- Engine-mounted duplex oil filter

- Intermittent air prelube

- Continuous electric prelube

- Redundant prelube with continuous electric prelube andintermittent air prelube backup

- Oil pan drain valves

- Electric continuous prelube pump

- Lube oil heater

- Oil pump - gear drive

- Crankcase explosion relief valves

- Alarm and shutdown during abnormal operation

- PLC-based system provides protection, monitoring, andcontrol housed in a NEMA 4 (IP66) enclosure.

- Service Literature

Optional Equipment

- 90° adapter and straight adapters for air inlet to turbochargerAir cleaners

- Air cleaners with Cat dry paper filter elements (approximately99.9% efficient at filtering SAE fine dust)

- Soot filter

- 4-20 mA load feedback signal

- Load sharing module

- Direct rack module

- Separate Circuit Aftercooler (SCAC)

- Customer water connections

- Jacket water thermostats

- AC/OC thermostats

- Accessory module-mounted high volume expansion tank

- Jacket water heater

- Heat recovery connections and thermostats for use withwater maker system

- ANSI connection adapters

- Exhaust manifold shields

- Vertical or 30° outboard exhaust orientation options

- Exhaust outlet expanders and weld flanges

- Manual fuel priming pump

- Duplex primary fuel strainer

- Flexible fuel hose connections

- Dry engine-mounted sump system that gravity feeds intobase assembly integral sump

- Engine-mounted duplex oil filter

- Intermittent air prelube

- Continuous electric prelube

- Redundant prelube with continuous electric prelube andintermittent air prelube backup

- Oil pan drain valves

- Electric continuous prelube pump

- Lube oil heater

- Wiring meets MCS requirements

- Upgrade PLC monitor to industrial PC

- Upgrades AC/OC, JW and start air pressure from contactorsto transducers

- Raw water/sea water pressure transducer

- Modbus communication

- Beacon and horn

- Single engine remote display monitor

- Emergency pump start signal

- Cabinet cooler

- Generator power monitoring

- Remote relay panel

- Turbocharger speed sensors

- Cylinder pressure relief valve

- Oil mist detector

- Flywheel and damper guards

- Base aseembly

- Vertically-restrained vibration isolators and weld plates

- Single turbine air starters

- Boost control valve for extremely cold ambient conditions

- Air start pressure reducing valves

- Torsional couplings

- Mounting groups for engine, generator, and base

- Accessory module to mount attachments such as theexpansion tank, heat exchanger, instrument panel andengine controls, annunciator panel, alarm and shutdowncontactors, fuel strainer

- Flywheel

- Engine barring device options:

- One-year storage preservation

- Oceanic transportation shipping protection (shrink wrapand tarp)

- Engine testing — certified dynamometer test, fuelconsumption test, rated speed performance test, overloadtest, minimum power setting, peak firing pressure test,turbo work cert and crankshaft work cert

- Standard and project-specific witness testing

- Spare parts kits

- Project-specific installation drawings

- Electrical schematics and P&ID drawings