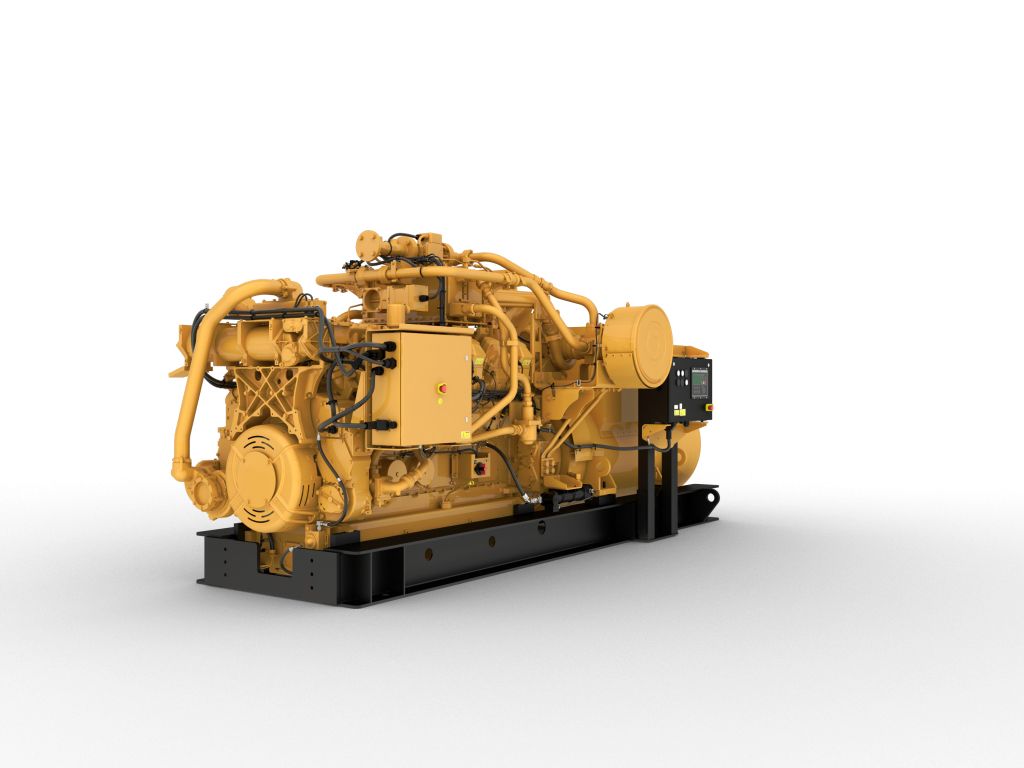

G3512 Gas Generator Sets, Oil & Gas

Contact Us For Price

SPECS SUMMARY

| Emissions/Fuel Strategy | U.S. EPA Tier 2 S.I. Non Road Mobile |

| Aspiration | Turbocharged-2 stage after cooled |

| Bore | 6.7 in (170 mm) |

| Stroke | 7.5 in (190 mm) |

Specifications

| Emissions/Fuel Strategy | U.S. EPA Tier 2 S.I. Non Road Mobile |

| Aspiration | Turbocharged-2 stage after cooled |

| Bore | 6.7 in (170 mm) |

| Stroke | 7.5 in (190 mm) |

| Displacement | 3173 in³ (52 l) |

| Engine Control and Protection | Electronic (ADEM 4) |

| Generator Set Control | EMCP 4.4 Control Panels |

| Length | 196 in (4979.3 mm) |

| Width | 84.8 in (2154.4 mm) |

| Height | 89.6 in (2277.1 mm) |

| Frequency - Speed | 60 Hz |

| Fuel System | Electronic Fuel Control Valve |

Benefits and Features

- Meets U.S. EPA Large SI Tier 2.*

- Genset designed to be paired with the Cat® energy storage system for a complete drilling factory solution

- Engine design built on the G3500 platform with proven reliability and durability

- EMCP 4.4 shipped standard • Jacket water and lube oil heaters shipped standard

- Rugged package base designed for oil fields

Lean air/fuel mixture provides best available emissions and fuel efficiency for engines of this bore size

ADEM™4 (A4) engine management system integrates speed control, air/fuel ratio control, and ignition/detonation controls into a complete engine management system. The ADEM™4 (A4) has an improved: user interface, display system, shutdown controls, and system diagnostics.

Large variety of factory-installed package attachments reduces packaging time

Every genset is full-load tested to ensure proper package performance.

Standard Equipment

- Air cleaner, intermediate duty, with service indicator and air filter differential pressure sensors

- Jacket water outlet- right hand flange connection

- Jacket water pump, gear driven, centrifugal, non - priming

- Dry exhaust manifold

- 10-35 kPag gas supply

- EMCP 4.4

- ADEM™4

- Crankcase breather - top mounted

- Prelube pump

- Simplex oil filter

- Standard Oil Pan

Optional Equipment

- Pre-cleaners

- Charging alternator 24V, 35A

- Left hand flanged jacket water connection

- Exhaust weld flange

- Gas train

- Electric prelube

- Air prelube

- Oil level regulator

- Oil drain

- Barring group

- Right hand air starter